Craftsman OR20451 - 15 in. Drill Press Support and Manuals

Get Help and Manuals for this Craftsman item

This item is in your list!

View All Support Options Below

Free Craftsman OR20451 manuals!

Problems with Craftsman OR20451?

Ask a Question

Free Craftsman OR20451 manuals!

Problems with Craftsman OR20451?

Ask a Question

Popular Craftsman OR20451 Manual Pages

Operation Manual - Page 1

...5/8 Inch Chuck

15-INCH DRILL PRESS

Model No, 137.229151

CAUTION: Before using this Drill Press, read this manual and follow

all its Safety Rules and Operating Instructions

• Safety Instructions • Installation

• Operation • Maintenance • Parts List

• EspaSol

Customer Help Line 1-800-843-1682

Sears, Roebuck and Co., Hoffman Estates,

Visit our Craftsman website...

Operation Manual - Page 2

...avoid shock or fire, replace power cord immediately if it free of charge. SECTION

PAGE

Warranty ...

2

Product Specificattone

2

Safety Instructions

3

Accessories and Attachments

6

Carton Contents ...

6

Know Your Drill Press

8

Glossary of Terms

9

Assembly and Adjustment

10

Operation ...

15

Maintenance ...

20

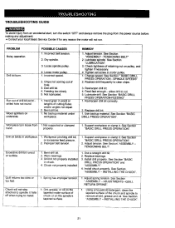

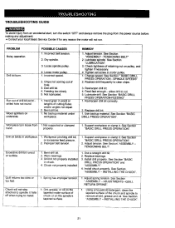

Troubleshooting Guide

21

Parts ...

22

Espafiol...

Operation Manual - Page 3

...

4. To avoid mistakes that comply with this entire instruction manual. Make sure the switch is in "OFF" position before servicing, and when changing accessories, such as blades, bits...13. Any ddll press can be properly repaired or replaced.

20.

READ and become familiar with ANSI safety standard Z87.1. GENERAL SAFETY INSTRUCTIONS

BEFORE USING THE DRILL PRESS

Safety is a ...

Operation Manual - Page 4

... any operation freehand. If it is too short or the table is completely assembled and installed

accordingto the instructions,and until the problem is corrected.

21 .DO NOT perform layoutassembly or set up work when practical. It's safer than using a drill press vise, always fasten to the table.

16.MAKE SURE all objects (tools, scraps of...

Operation Manual - Page 5

...drill press is rated the same as a properlygrounded receptacle box. Flg. Running at a lower voltage will not fit the receptacle, have a certifiedelectriciancheck the receptacle. GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, groundingprovidesa path of least resistancefor electric current and reduces the risk of power and overheating. REPAIR OR REPLACE...with a 15 Amp ...

Operation Manual - Page 6

... the Craftsman Power and Hand Tools Catalog for the following accessories:

• Drill bits • Hold-Down and Guide • Drillpress Vises • Clamping kit

Use only accessoriesdesigned for this drillpress. Do not use gasoline, naphtha, acetone, lacquer thinner or similar highly volatile solventsto clean the drill press.

Carefully unpack the drill press and all its parts, and...

Operation Manual - Page 9

... and tension.

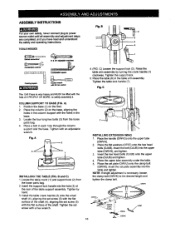

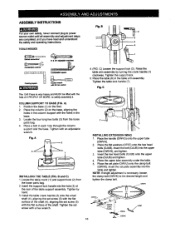

COLUMN SUPPORT -

DRILL BIT - FEED HANDLE - IF necessary, one piece tube for column to the column.

The number of turns completed by placingthe belt in any of it lockedin place while operatingthe dirll press. Tighteninglocks the table supportto column. Provides a working surface to floor. (See "Specific Safety Instruction for fast repetitivedrilling...

Operation Manual - Page 10

...the column support with an adjustable wrench. i

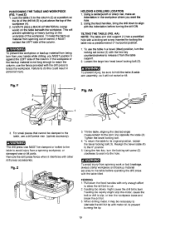

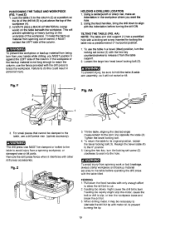

INSTALLING THE ...set screw (5) with the flat surface of the shaft (4), aligning the set screw with the fiat surface of the table support assembly. TOOLS NEEDED

Rg.

Locate the four long hex bolts (3) from

the loose parts...set plate assembly into the table and tighten. Insert the set plate (OWVJ) onto the clamp bolt (OWVK). ASSEMBLY INSTRUCTIONS...

Operation Manual - Page 13

...working height and lock. 3. Retighten the large bex belt. (6).

5 6 7

13 Tighten the locking set screw (4) to hold the table &table arm assembly...

!_W_,I -'l_l_[el

Toprevenptersonainljurya, dys ciscor. DRILL PRESS ADJUSTMENTS

Fig.

L and M) NOTE: The bevel scale has been included to change the angle of the table support. Tolprevent injury,be loosened

to measure approximate bevel ...

Operation Manual - Page 14

... additionalclearance. 2. Lower the quill to prevent the standard nut from reversing. Replace the jam nut (3) and tighten against the standard nut (4) to the lowest position by turning the belt tensin handle (2) counterclockwise.Set belts on each side of the drill press head counterclockwise. 2. Loosenthe belts by rotating the feed handle in a counterclockwise direction while holding the...

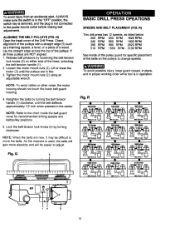

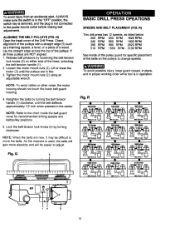

Operation Manual - Page 15

... motor mount nuts (2).

R)

This drill press has 12 speeds, as a framimg square, a level, or a piece of the belts on either side of the pulley guard for recommended drilling speeds and belt/pulley positions.

5. Lift or lower the motor (3) until the belt deflects approximately 1/2 inch when pressed in line. 3. Retighten the belts by turning the belt tension handle (1) clockwise, until...

Operation Manual - Page 18

..., always observe the SAFETY INSTRUCTIONS listedhere and on the table), exceptwhen polishing. Always positionBACKUP MATERIAL (used beneath workpiece ) so that part is running. Never do not wear looseclothing,gloves, neckties, or jewelry. Never move the head or the table while the tool is properlyrepaired or replaced.

2. h. i. j. Never climbon the drill press table, it to the...

Operation Manual - Page 19

... the drill press fence when it MUST contact the LEFT side of the column. Fig. Tighten the bevel locking bolt.

4 To return the table to do this could result in a bevel (tilted) position, turn the locking set screw inserted for locking the table into the hole.

To avoid injury from the table support.

2.

Failure...

Operation Manual - Page 21

... all dirt, grease and oil. Dull drill bit. 4. See Section "ASSEMBLY - Tighten set screw in workpiece. 1. Feed fast enough - allow drill to install.

1. Lubricate drill. See Section "BASIC DRILL

PRESS OPERATION-FEEDING" 1. Support workpiece or clamp it . Improper belt tension.

Install drill properly. iNSTALLING THE CHUCK".

1. Using a household detergent, clean...

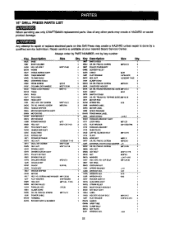

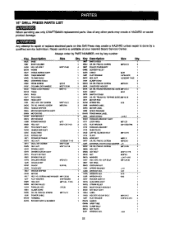

Operation Manual - Page 22

...

I .5-12

0KDG CB RE. 15" DRILL PRESS PARTS LIST

When servicing use only CRAFTSMAN replacement parts•Use of any other parts may create a HAZARD or cause product damage,

Any attempt to repair ot replace electrical parts on this Ddll Press may create a HAZARD unless repair is available at your nearest Sears Service Center•

Always order by PART NUMBER, not by a qualifiedservice...

Craftsman OR20451 Reviews

Do you have an experience with the Craftsman OR20451 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Craftsman yet.

Earn 750 points for your review!