Craftsman 21914 - 12 in. Drill Press Support and Manuals

Get Help and Manuals for this Craftsman item

View All Support Options Below

Free Craftsman 21914 manuals!

Problems with Craftsman 21914?

Ask a Question

Free Craftsman 21914 manuals!

Problems with Craftsman 21914?

Ask a Question

Most Recent Craftsman 21914 Questions

How To Remove The Chuck From A Craftsman 9 Drill Press

(Posted by v12Ashr 9 years ago)

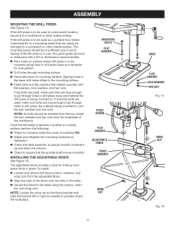

Assembly Video

is there an online video on how to assemble the 12" drill press?

is there an online video on how to assemble the 12" drill press?

(Posted by davisgirl51 10 years ago)

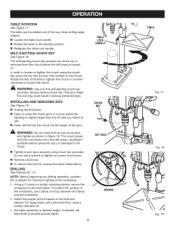

Craftsman 21914 Quill Distance?

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

(Posted by remondi 12 years ago)

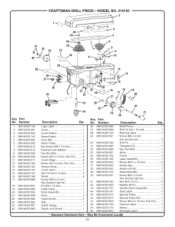

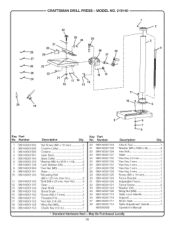

Popular Craftsman 21914 Manual Pages

Craftsman 21914 Reviews

We have not received any reviews for Craftsman yet.