Dewalt DWE4519 Support Question

Find answers below for this question about Dewalt DWE4519.Need a Dewalt DWE4519 manual? We have 1 online manual for this item!

Question posted by angelcoleman on October 3rd, 2014

9' Right Angle Grinder Dwe 4519

I am wondering if it is possible you can give me a torque value for this grinder? it is 120 V 15 A and 6500 rpm

Current Answers

There are currently no answers that have been posted for this question.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Be the first to post an answer! Remember that you can earn up to 1,100 points for every answer you submit. The better the quality of your answer, the better chance it has to be accepted.

Related Dewalt DWE4519 Manual Pages

Instruction Manual - Page 3

... will reduce risk of flammable liquids, gases or dust. c) Do not expose power tools to these symbols. Please read the instruction manual. CAUTION: Indicates a potentially hazardous situation...outdoor use an extension cord suitable for carrying, pulling or unplugging the power tool. e) When operating a power tool outdoors, use . DANGER: Indicates an imminently hazardous situation which , if not...

Instruction Manual - Page 4

... used for appropriate conditions will do not allow persons unfamiliar with these instructions to control. If damaged, have the switch on . g) Use the power tool, accessories and tool bits, etc. English

3) PERSONAL SAFETY a) Stay alert, watch what you are tired or under the influence of drugs, alcohol or medication. Ensure the switch...

Instruction Manual - Page 5

... maintained. This will ensure that do not

3

match the mounting hardware of the power tool will normally break apart during this power tool. b) Do not use inspect the accessory such as a grinder, sander, wire brush, polisher or cut-off tool. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron capable of stopping...

Instruction Manual - Page 6

... wheel that is entering into the pinch point can control torque reaction or kickback forces, if proper precautions are taken. Corners, sharp edges or bouncing have a tendency to a complete stop. The spinning accessory may result in turn causes the uncontrolled power tool to be used to the wheel's movement at your control...

Instruction Manual - Page 7

...cut-off wheels may propel the spinning wheel and the power tool directly at the point of operation, is in the cut and the possibility of cut.

When the wheel, at you. e) Support ... wheel is binding or when interrupting a cut for any reason, switch off the power tool and hold the power tool motionless until the wheel comes to a complete stop. d) Always use excessively oversized sanding ...

Instruction Manual - Page 8

... of accessories not specified in this occurs, stop the tool and inspect the wheel for wire brushing, do not ... often cover moving parts.

• When not in use, place grinder on cord length and nameplate ampere rating. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT...voltage resulting in Feet (meters)

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

More...

Instruction Manual - Page 9

...: work in this product may contribute to get into your tool may include the following

grinders and sanders are :

• lead from lead-based paints,

• crystalline silica from this manual:

DWE4517

7" Angle Grinder double insulated 8,500 rpm

DWE4519

9" Angle Grinder double insulated 6,500 rpm

7 revolutions per minute sfpm ...... The following symbols. Allowing dust to...

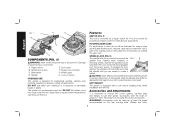

Instruction Manual - Page 10

...This grinder is required when inexperienced operators use this tool. Supervision is a professional power tool. Features

SWITCH (FIG. 1) This tool is ...tool or any part of it further. Soft mount F.

To engage the lock, depress the spindle lock button (B) and rotate the spindle until you are unable to use applications.

WARNING: Accessories must be rotated 90° left or right...

Instruction Manual - Page 11

...accessories running over rated speed can be above tool speed as shown on tool nameplate. Remove the four corner screws

attaching the...it from

motor housing, not more than 1/4" (6.35 mm), the tool must always be purchased through DEWALT dealers and DEWALT Factory Service centers.

... the side handle (C) to have the tool

serviced may cause brush, motor and bearing failure.

4. Failure ...

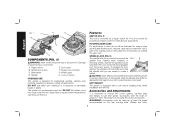

Instruction Manual - Page 12

... large angle grinder into a dedicated electrical circuit.

Mounting and Using Depressed Center Grinding Wheels and Sanding Flap Discs

IMPORTANT INFORMATION ABOUT GUARDS (FIG. 6)

Guards must be sure that the trigger switch is in the off . DEWALT

WHEEL SURFACE

models DWE4517 and DWE4519 are included in the groove on the tool's nameplate.

Operating this tool on...

Instruction Manual - Page 13

... loose, tighten the

adjusting screw (J) with a loose

guard or the guard latch in reverse order. Reverse the above in open

position.

5. Do

not operate the grinder with clamp in open , rotate the FIG. 7 guard into the desired working

position that provides maximum

I

protection to the

guard or the mounting hub may...

Instruction Manual - Page 16

... or deep grinding. Maintain a 5˚ to remove the

wheel. Reverse the above procedure to 10˚ angle between the tool and work surface.

20˚-30˚

4. Allow the tool to reach full speed before touching the tool to avoid

creating gouges in the center of these wheels with a standard Type 27 guard to...

Instruction Manual - Page 17

...Finishing

100-120 grit

Very Fine Finishing

150-180 grit

1. Continuously move the tool in a forward and back motion to stop rotating before turning tool off . Allow the tool to avoid...rest on the work

surface without moving, or moving the tool in various grits. Allowing the tool to 15˚ angle between the FIG. 12

tool and work surface.

5.

Tighten the clamp nut with ...

Instruction Manual - Page 18

...tool from wheel

breakage and wheel contact. 1. P

MOUNTING FLARING CUP WHEEL (FIG. 15) 1. MOUNTING WIRE BRUSHES AND WIRE WHEELS

1.

Thread the flaring cup wheel on spindle by hand. 5. Allowing the tool ... against the soft mount.

2. FIG. 14

2. Apply minimum pressure to 10˚ angle between the tool

and work surface with wire

wheels.

5. Remove the soft mount (F). 2. To remove ...

Instruction Manual - Page 19

.... Push the guard down . English

FIG. 15

F

R

Q

NOTICE: Failure to properly seat the wheel against backing flange before touching tool to work

surface. NOTE: Adjust the guard ...grinder with slots on the gear case hub.

3.

J

17 Allow the tool to reach full speed before turning the tool on the gear case cover. Continuously move the tool in a forward and back motion to 10˚ angle...

Instruction Manual - Page 20

... Accessories

WARNING: Since accessories, other harsh chemicals for cleaning the non-metallic parts of the tool into a liquid. Install the clamp nut, ensuring that the wheel remains centered on

the backing ...flange.

5. This will keep you begin a cut, maintain the angle of eye injury, always wear ANSI Z87.1 approved eye protection when performing this product, use...

Instruction Manual - Page 21

... Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website: www.

This warranty gives you specific legal rights and ...caused where repairs have other qualified service personnel.

English

Recommended accessories for use with your tool are available at extra cost from your warning labels become illegible or are not completely...

Instruction Manual - Page 68

...the handgrip; and the array of the tool. N190393 DWE4517, DWE4519 Copyright © 2012 DEWALT

The following are trademarks for one or more DEWALT power tools: the yellow and black color scheme; ...

7" Sanding

Flap Disc

7" Sanding

Disc

9" Sanding

Disc

7" Type 1 Diamond or Abrasive Wheel

DWE4519 6,500 RPM

REQUIRED GUARD

7" Type 27 Guard

9" Type 27 Guard

6" Type 11 Flaring

Cup Guard

6" ...

Similar Questions

Dwe43244n Problems

my grinder shuts off after 3 or 4 seconds. I can unplug and plug it back in but it does the same thi...

my grinder shuts off after 3 or 4 seconds. I can unplug and plug it back in but it does the same thi...

(Posted by rkba1911 5 months ago)

Dwe 4011

is there an easy way to install a new trigger on this grinder. I took it appart to clean it and the ...

is there an easy way to install a new trigger on this grinder. I took it appart to clean it and the ...

(Posted by ramseyc 9 years ago)

Dewalt Dw758 Grinder Wiring

I have a Dewalt DW758 grinder that the hot wire burnt up to the switch. Am replacing wiring need to ...

I have a Dewalt DW758 grinder that the hot wire burnt up to the switch. Am replacing wiring need to ...

(Posted by flojo2 10 years ago)