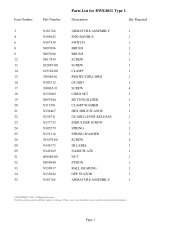

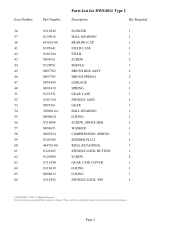

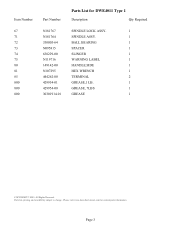

Dewalt DWE4011 Support Question

Find answers below for this question about Dewalt DWE4011.Need a Dewalt DWE4011 manual? We have 2 online manuals for this item!

Question posted by ramseyc on June 5th, 2014

Dwe 4011

is there an easy way to install a new trigger on this grinder. I took it appart to clean it and the plastic slide that the trigger snaps into broke, so i had to replace the slide, but now cannot get the trigger switch snapped back into the slide.

Current Answers

Answer #1: Posted by TechSupport101 on June 6th, 2014 2:17 AM

Hi. You should be able to obtain expert technical assistance here http://www.dewalt.com/parts-and-service.aspx

Related Dewalt DWE4011 Manual Pages

Similar Questions

Dcb 100 12v Battery Charger

Haven't used in a while. Manual M I A. How to connect battery to charger??? My thinking is the batte...

Haven't used in a while. Manual M I A. How to connect battery to charger??? My thinking is the batte...

(Posted by anotherway2live 9 years ago)

9' Right Angle Grinder Dwe 4519

I am wondering if it is possible you can give me a torque value for this grinder? it is 120 V 15 A a...

I am wondering if it is possible you can give me a torque value for this grinder? it is 120 V 15 A a...

(Posted by angelcoleman 9 years ago)

Job Radio

Hi I have an older 14v radio/charger. Had it plugged in when I had problem with the powerline to my...

Hi I have an older 14v radio/charger. Had it plugged in when I had problem with the powerline to my...

(Posted by jeffonplacidlake 11 years ago)