Brother International CB3-B917 Support Question

Find answers below for this question about Brother International CB3-B917.Need a Brother International CB3-B917 manual? We have 2 online manuals for this item!

Question posted by deekayknitwear on April 8th, 2015

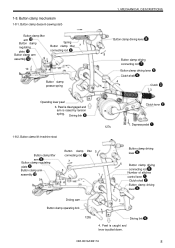

How To Thread This Machine

how do i thread this machine?

Current Answers

Answer #1: Posted by TommyKervz on April 9th, 2015 5:08 AM

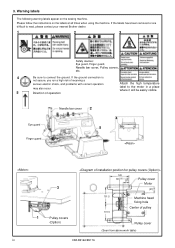

Download a user guide on the link http://www.helpowl.com/manuals/Brother%20International/CB3B917/154895 and start reading from page 9

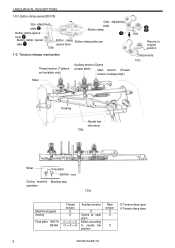

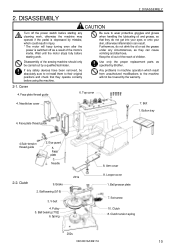

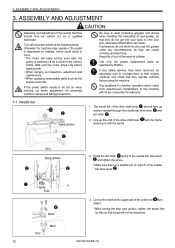

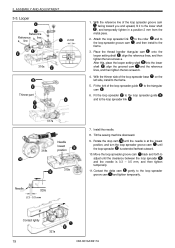

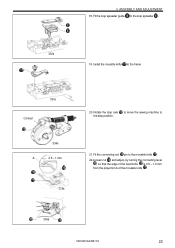

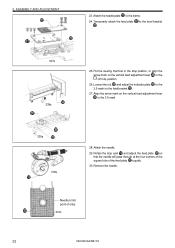

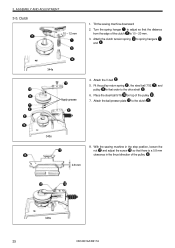

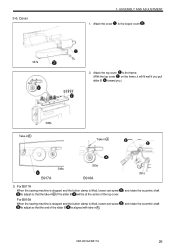

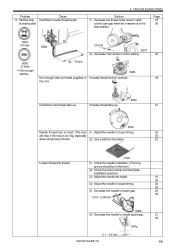

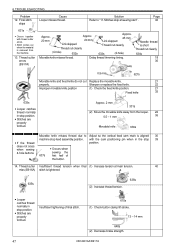

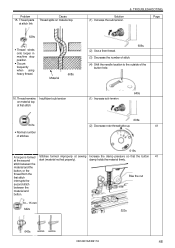

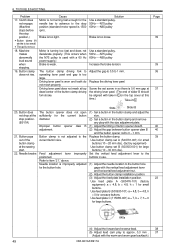

Related Brother International CB3-B917 Manual Pages

Similar Questions

Why Won't My Needle Thread..machine Is Only 1 Month Old.

(Posted by cyndibrown01 9 years ago)

Need To Know How To Thread Machine

received from friend who lost instruction book don't know how to the thread goe's to needle

received from friend who lost instruction book don't know how to the thread goe's to needle

(Posted by ardellaforsyth 11 years ago)