Brother International CB3-B917 Support and Manuals

Get Help and Manuals for this Brother International item

View All Support Options Below

Free Brother International CB3-B917 manuals!

Problems with Brother International CB3-B917?

Ask a Question

Free Brother International CB3-B917 manuals!

Problems with Brother International CB3-B917?

Ask a Question

Most Recent Brother International CB3-B917 Questions

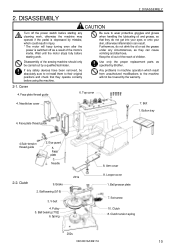

Brother Presser Arm

press arm does not lift after sewing button on what could be the problem

press arm does not lift after sewing button on what could be the problem

(Posted by rarebirdhandbags 10 years ago)

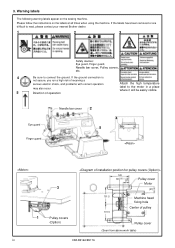

Popular Brother International CB3-B917 Manual Pages

Brother International CB3-B917 Reviews

We have not received any reviews for Brother International yet.