Ryobi TSS101L Support Question

Find answers below for this question about Ryobi TSS101L.Need a Ryobi TSS101L manual? We have 4 online manuals for this item!

Question posted by billgovan45 on September 6th, 2011

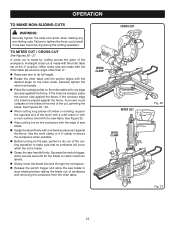

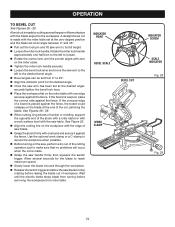

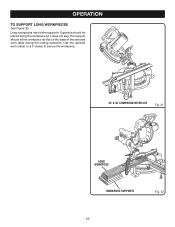

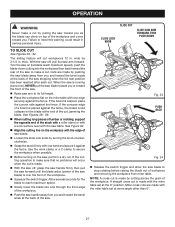

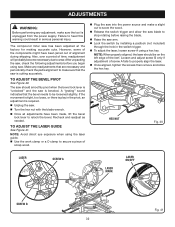

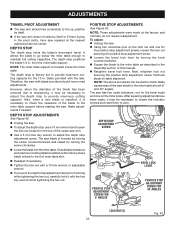

How To Operate The Slide Bar.

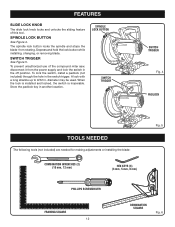

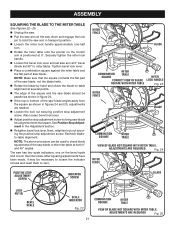

I loosened the Slide Lock Knob.Bevel lock lever is opened. The Slide Bar seems to be stuck. No sliding to make cut

Current Answers

Related Ryobi TSS101L Manual Pages

Similar Questions

Is There A Replacement For Ryobi Tss101l D Handle & Switch?

Part #s for above: 089100121610 089100121112 Have apparently discontinued. Does anyone have a fix?

Part #s for above: 089100121610 089100121112 Have apparently discontinued. Does anyone have a fix?

(Posted by Math72285 3 years ago)

How To Replace The Bevel Lock Washer On A Ryobi Rts30

(Posted by mike1QWJani 10 years ago)

Ryobi Tss101l Laser Not Working?

I have a brand new Ryobi TSS101L and I see no evidence of a laser working. I looked through the manu...

I have a brand new Ryobi TSS101L and I see no evidence of a laser working. I looked through the manu...

(Posted by linexyc 11 years ago)

Ryobi Tss101l Won't Start.

My 10" mitre saw is getting electricity to the switch and when I pull the trigger the current return...

My 10" mitre saw is getting electricity to the switch and when I pull the trigger the current return...

(Posted by dtwood1 11 years ago)

Charger Has Green Light But Will Not Operate Any Of My Tools

riboyi lithium 18v P103 battery has a green light from charger but will not run andy of my tools

riboyi lithium 18v P103 battery has a green light from charger but will not run andy of my tools

(Posted by jmschaefer 12 years ago)