Ryobi RTS12 Support Question

Find answers below for this question about Ryobi RTS12.Need a Ryobi RTS12 manual? We have 3 online manuals for this item!

Question posted by coreyhubbardbiz on March 21st, 2022

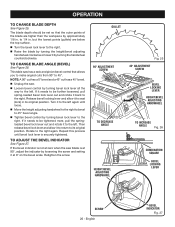

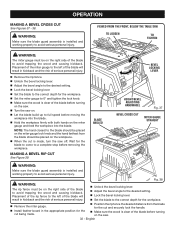

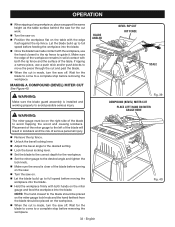

How Do You Adjust The Positive Stops?

My blade isn't at 90 degrees. The manual says adjust the positive stops but I can't find where it says how.

Current Answers

Answer #1: Posted by SonuKumar on March 22nd, 2022 6:49 AM

https://www.youtube.com/watch?v=mUUQeHo6et4

or

https://manualzz.com/doc/24483193/ryobi-rts12-10-in.-table-saw-owner-manual

manual remcommeded

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Ryobi RTS12 Manual Pages

Similar Questions

Ryobi 10" Table Saw Dado Throat Plate

where can I find a dado throat plate for the Ryobi 10" table saw?

where can I find a dado throat plate for the Ryobi 10" table saw?

(Posted by Rick52757 2 years ago)

In Manual For Ryobi Model Rts10 Instructions For Setting Blade At 0 Or 90

states that it may be necessary to remove indicator with red line to 0. How do I remove the indicato...

states that it may be necessary to remove indicator with red line to 0. How do I remove the indicato...

(Posted by theduckfan88 9 years ago)

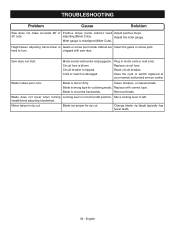

Blade Stopping

I was recently given this table saw. Well shortly after turning it on the saw will make a sound and ...

I was recently given this table saw. Well shortly after turning it on the saw will make a sound and ...

(Posted by Dbaker85 9 years ago)

Where Are The Positive Stops Inside The Cabinet? Need To Make Adjustments For

I need to make adjustments for a 90 degree cut.

I need to make adjustments for a 90 degree cut.

(Posted by rnicot 10 years ago)