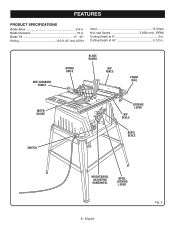

Ryobi RTS12 Support Question

Find answers below for this question about Ryobi RTS12.Need a Ryobi RTS12 manual? We have 3 online manuals for this item!

Question posted by sharma20 on September 27th, 2022

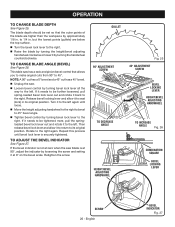

Blade Maximum Height

Current Answers

Answer #1: Posted by SonuKumar on September 27th, 2022 8:07 AM

page 47- troubleshooting

Not sure what is the cause for it

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Answer #2: Posted by hzplj9 on September 27th, 2022 8:13 AM

https://www.manualowl.com/p/Ryobi/RTS12/Manual/298078#google_vignette

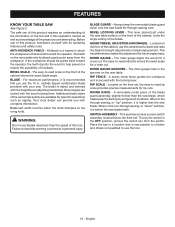

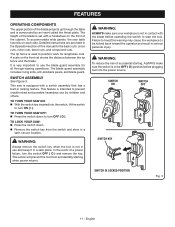

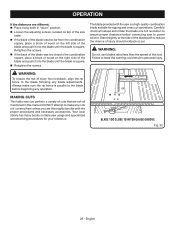

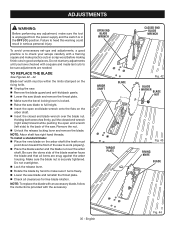

It may need to be re-adjusted to enable the blade lever to align correctly.

Hope that helps you solve it.

Related Ryobi RTS12 Manual Pages

Similar Questions

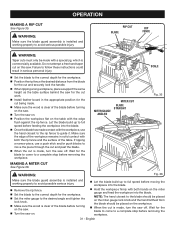

My blade isn't at 90 degrees. The manual says adjust the positive stops but I can't find where it sa...

where can I find a dado throat plate for the Ryobi 10" table saw?

I just got a new table saw and cannot raise the saw blade height. please help.