Ryobi P213 Support Question

Find answers below for this question about Ryobi P213.Need a Ryobi P213 manual? We have 8 online manuals for this item!

Question posted by martinb4 on August 1st, 2015

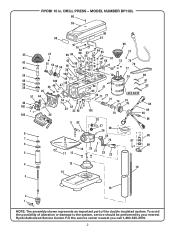

Is P213 The One I Want For My Dp102l Drill Press

ok im looking for a manual for my DP102L RYOBI 10 inch drill press, and I want to know if the P213 will suffice ?

Current Answers

Answer #1: Posted by Odin on August 1st, 2015 11:41 AM

Go to http://www.manualslib.com/r/ryobi+dp102l.html. The manual you want is probably the first listed.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Related Ryobi P213 Manual Pages

Similar Questions

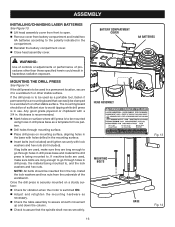

Ryobi Drill Press Lazer Not Working Brand New

my laser not working brand new and batteries is fitted

my laser not working brand new and batteries is fitted

(Posted by johanwessels06 1 year ago)

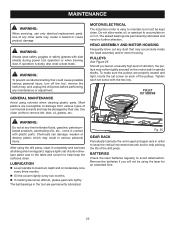

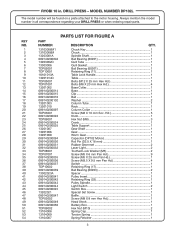

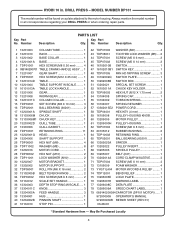

I Am Looking For A Part For The Ryobi 12 In. Drill Press W/ Laser Model Dp121l

My name is Carlos Alvarez, from Mexico, and I'm looking for part 27. 13303001A SPINDLE. Can you help...

My name is Carlos Alvarez, from Mexico, and I'm looking for part 27. 13303001A SPINDLE. Can you help...

(Posted by alvarezmc 2 years ago)

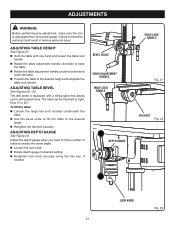

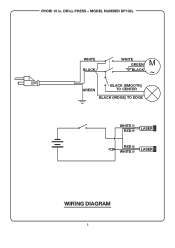

I Did Not Pay Attention To What Wires Go Where On Switch Replacement.

I do not understand the symbols on the electrical schematics for the DP102L drill press

I do not understand the symbols on the electrical schematics for the DP102L drill press

(Posted by jajzksb 8 years ago)

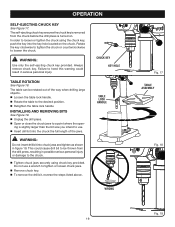

How Do You Adjust The Lazer On The Ryobi Dp121l Drill Press?

(Posted by rtrobaugh 9 years ago)