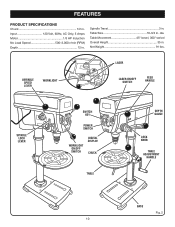

Ryobi DP121L Support Question

Find answers below for this question about Ryobi DP121L.Need a Ryobi DP121L manual? We have 5 online manuals for this item!

Question posted by alvarezmc on April 8th, 2022

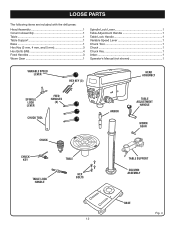

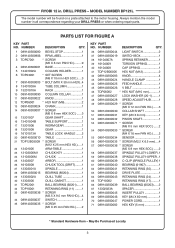

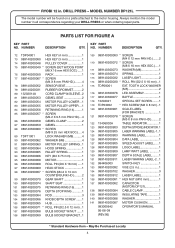

I Am Looking For A Part For The Ryobi 12 In. Drill Press W/ Laser Model Dp121l

Current Answers

Answer #1: Posted by Odin on April 8th, 2022 3:06 PM

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Answer #2: Posted by SonuKumar on April 8th, 2022 8:22 PM

https://www.repairtoolparts.com/ryobi-parts/ryobi-dp121l-parts-list

https://www.toolpartspro.com/ryobi-parts/ryobi-dp121l-parts.html

https://www.fix.com/models/drill-press/ryobi/id772779/dp121l/

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Ryobi DP121L Manual Pages

Similar Questions

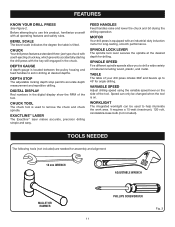

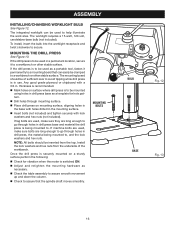

my laser not working brand new and batteries is fitted

ok im looking for a manual for my DP102L RYOBI 10 inch drill press, and I want to know if the P213 w...

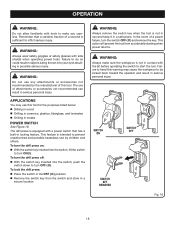

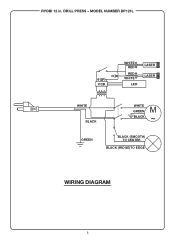

Is the a diagram for the wireing.