Ryobi DP121L Support Question

Find answers below for this question about Ryobi DP121L.Need a Ryobi DP121L manual? We have 5 online manuals for this item!

Question posted by Bmorma on March 9th, 2014

How To Use Ryobi Drill Press Dp121l

The person who posted this question about this Ryobi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

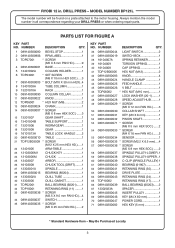

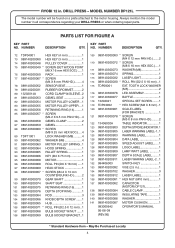

Related Ryobi DP121L Manual Pages

Similar Questions

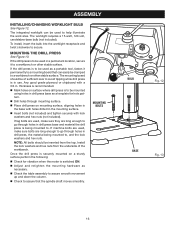

Ryobi Drill Press Lazer Not Working Brand New

my laser not working brand new and batteries is fitted

my laser not working brand new and batteries is fitted

(Posted by johanwessels06 1 year ago)

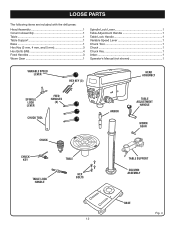

I Am Looking For A Part For The Ryobi 12 In. Drill Press W/ Laser Model Dp121l

My name is Carlos Alvarez, from Mexico, and I'm looking for part 27. 13303001A SPINDLE. Can you help...

My name is Carlos Alvarez, from Mexico, and I'm looking for part 27. 13303001A SPINDLE. Can you help...

(Posted by alvarezmc 2 years ago)

Is P213 The One I Want For My Dp102l Drill Press

ok im looking for a manual for my DP102L RYOBI 10 inch drill press, and I want to know if the P213 w...

ok im looking for a manual for my DP102L RYOBI 10 inch drill press, and I want to know if the P213 w...

(Posted by martinb4 8 years ago)

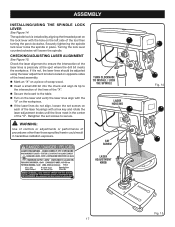

How Do You Adjust The Lazer On The Ryobi Dp121l Drill Press?

(Posted by rtrobaugh 9 years ago)

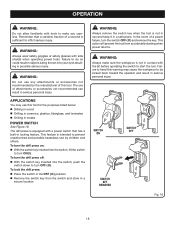

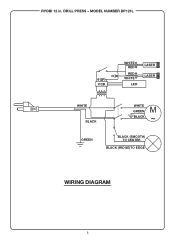

I Had To Put A New Switch On My Dp121l But Take Notice Of What Wire Went Where.

Is the a diagram for the wireing.

Is the a diagram for the wireing.

(Posted by edwardrecker 12 years ago)