Ryobi DP102L Support and Manuals

Get Help and Manuals for this Ryobi item

View All Support Options Below

Free Ryobi DP102L manuals!

Problems with Ryobi DP102L?

Ask a Question

Free Ryobi DP102L manuals!

Problems with Ryobi DP102L?

Ask a Question

Most Recent Ryobi DP102L Questions

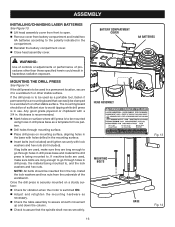

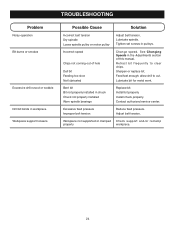

Ryobi Drill Press Lazer Not Working Brand New

my laser not working brand new and batteries is fitted

my laser not working brand new and batteries is fitted

(Posted by johanwessels06 1 year ago)

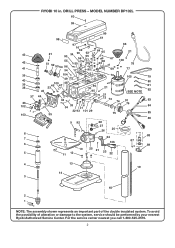

Pulley Shaft Hold Down Nut Approximately 5/8 Fine Threads

the schematic shows a 1 inch X 20 nut 1 inch is way too la

the schematic shows a 1 inch X 20 nut 1 inch is way too la

(Posted by Garliced 1 year ago)

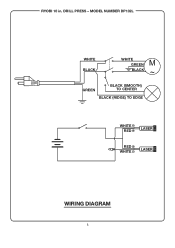

Machine Is Not Turning On When Inserting Key And Pushing Up Key Pops Out?

(Posted by estherflam 2 years ago)

Ryobi DP102L Videos

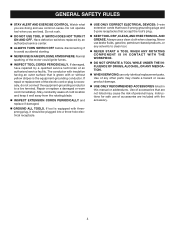

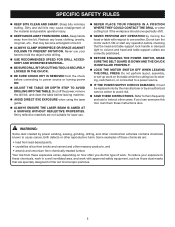

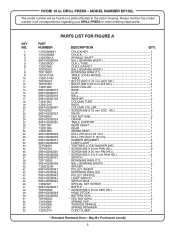

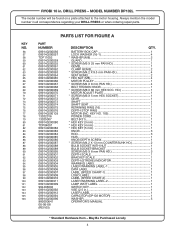

Popular Ryobi DP102L Manual Pages

Ryobi DP102L Reviews

We have not received any reviews for Ryobi yet.