Harbor Freight Tools 67847 Support Question

Find answers below for this question about Harbor Freight Tools 67847 - 21 gal. 2-1/2 HP 125 PSI Cast Iron Vertical Air Compressor.Need a Harbor Freight Tools 67847 manual? We have 1 online manual for this item!

Question posted by rubberducky0926 on May 10th, 2017

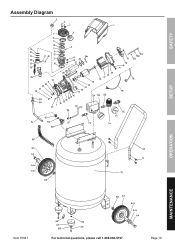

Model 67847 Central Pneumatic Air Compressor Parts

part#3 start plug and part#37 oil plug needed.

Requests for more information

Request from cfiventhmj on January 24th, 2021 2:28 PM

need crankshaft and connecting rod

need crankshaft and connecting rod

Current Answers

Answer #1: Posted by Odin on May 12th, 2017 7:16 AM

The first step is to check with the manufacturer: use the contact information here--https://www.contacthelp.com/Harbor%20Freight%20Tools/customer-service. If you can't get the part directly from the manufacturer, ask for a part number and (with or without a part number) follow the applicable suggestions at this previous answer.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Related Harbor Freight Tools 67847 Manual Pages

Similar Questions

Timing The Gear Set On Central Pneumatic 91773 Air File

(Posted by mop1960 6 months ago)

Looking For Kerf For Chicago Electric 98199 Miter Saw Part 21

(Posted by deknapp 11 months ago)

Where Can I Get A Rear Oil Seal For This Compressor, Also Is Recalls

can some one tell where i can get a rear compressor oil seal for this 2.5 hp 21 gal compressor and a...

can some one tell where i can get a rear compressor oil seal for this 2.5 hp 21 gal compressor and a...

(Posted by stperreirajr 1 year ago)

Looking For Kerf Part # 21

(Posted by granatomichael 2 years ago)