Ryobi SC164VS Support Question

Find answers below for this question about Ryobi SC164VS.Need a Ryobi SC164VS manual? We have 4 online manuals for this item!

Question posted by abirdboy on September 1st, 2016

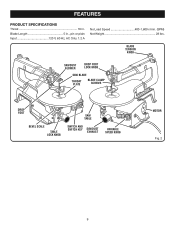

Ryobi Lower Blade Clamp

Where can I buy a ryobi sc164 scroll saw lower blade clamp?

Current Answers

Answer #1: Posted by Odin on September 1st, 2016 8:15 AM

All parts for this tool available in retail sale are listed (on the left) at http://www.repairclinic.com/Shop-For-Parts/b341d2052083/Model-SC164VS-Ryobi-Parts. If you don't see there what you seek, you might want to call Ryobi (see the contact information here--https://www.contacthelp.com/ryobi/customer-service); or consider the other options that may be applicable suggested at http://bit.ly/2bLr3JF.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

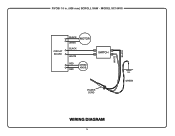

Related Ryobi SC164VS Manual Pages

Similar Questions

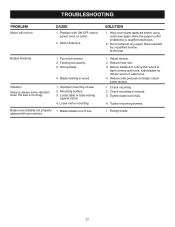

Can't Raise/lower Blade

Hello. There are 2 screws that go through a plate involved in raising and lowering the blade. One is...

Hello. There are 2 screws that go through a plate involved in raising and lowering the blade. One is...

(Posted by info10977 7 years ago)

Lower Blade Guard

My lower blade guard is stuck, any ideas on getting it loose?

My lower blade guard is stuck, any ideas on getting it loose?

(Posted by kendallbailey969 9 years ago)

How Do I Replace The Spring On My Ts1342l 10 Lower Blade Guard

(Posted by golfesxu 10 years ago)

Lower Blade Guard Ts1342l Miter Saw

How do I replace the spring on my TS1342L 10" lower blade guard?

How do I replace the spring on my TS1342L 10" lower blade guard?

(Posted by MRELVIS 12 years ago)