Ryobi RTS21 Support Question

Find answers below for this question about Ryobi RTS21.Need a Ryobi RTS21 manual? We have 12 online manuals for this item!

Question posted by info10977 on February 23rd, 2017

Can't Raise/lower Blade

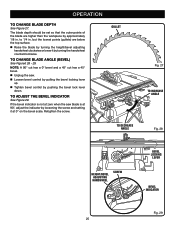

Hello. There are 2 screws that go through a plate involved in raising and lowering the blade. One is connected to the crank/handle used to raise the blade. It goes through the block which rides in a channel on one of the connected plates.The other seems to go through the plate and maybe supports the weight?? Anyway, my guess is that the nut on the supporting screw (it is threaded below the plate) must have come off which then caused the lock washer on the crank screw to come off (since it then supported all the force of raising and lowering) so the blade can't be moved. I tried putting a lock washer on the "supporting" screw but the lack washer on the crank screw keeps popping off and I doubt I will be able to get one to stay on since the groove it sits in is very shallow. The saw works fine except for this and I hate to trash it. The newer saws have a slightly different design and I was wondering if I can order the new parts and use them to fix the saw. Comments/suggestions??

Current Answers

Related Ryobi RTS21 Manual Pages

Similar Questions

Ryobi Lower Blade Clamp

Where can I buy a ryobi sc164 scroll saw lower blade clamp?

Where can I buy a ryobi sc164 scroll saw lower blade clamp?

(Posted by abirdboy 7 years ago)

Vibration In My Table Saw

I tried a 8in dia dado stack of 1/4 in, the saw vibrated so bad the blades retracted down in the saw...

I tried a 8in dia dado stack of 1/4 in, the saw vibrated so bad the blades retracted down in the saw...

(Posted by Lbtrail 8 years ago)

Lower Blade Guard

My lower blade guard is stuck, any ideas on getting it loose?

My lower blade guard is stuck, any ideas on getting it loose?

(Posted by kendallbailey969 9 years ago)

Lower Blade Guard Ts1342l Miter Saw

How do I replace the spring on my TS1342L 10" lower blade guard?

How do I replace the spring on my TS1342L 10" lower blade guard?

(Posted by MRELVIS 12 years ago)