Ryobi RTS30 Support Question

Find answers below for this question about Ryobi RTS30.Need a Ryobi RTS30 manual? We have 4 online manuals for this item!

Question posted by lkurpis on September 4th, 2011

How To Find Assembly Instructions In English

The person who posted this question about this Ryobi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Ryobi RTS30 Manual Pages

Similar Questions

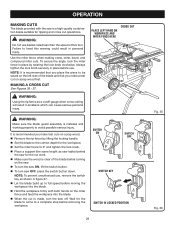

Riving Knife Issue's

I am having issue's with my tile binding up on the riving knife. I have tried adjusting it by loosen...

I am having issue's with my tile binding up on the riving knife. I have tried adjusting it by loosen...

(Posted by Anonymous-165466 5 years ago)

How To Replace The Bevel Lock Washer On A Ryobi Rts30

(Posted by mike1QWJani 10 years ago)

I Need The Manual For The Router Table, Not The Router Itself. Can't Find That!

Need parts list and assembly instructions for the router TABLE shown in the Ryobi R163RTA 'Combo', w...

Need parts list and assembly instructions for the router TABLE shown in the Ryobi R163RTA 'Combo', w...

(Posted by JulietBrown 10 years ago)

Install Kick Back Pawls Rts30

cant figure out how to put on this kickback pawls on table sawrts30

cant figure out how to put on this kickback pawls on table sawrts30

(Posted by fibb420 12 years ago)

Ryobi Rts30 Dado Throat Plate And Dado Blade

I am looking for the correct dado throat plate and dado saw blades for my Ryobi RTS30 10" table saw....

I am looking for the correct dado throat plate and dado saw blades for my Ryobi RTS30 10" table saw....

(Posted by daleemcmillan 12 years ago)