Ryobi RTS10 Support Question

Find answers below for this question about Ryobi RTS10.Need a Ryobi RTS10 manual? We have 4 online manuals for this item!

Question posted by ridingsdbd on July 13th, 2021

My Tablesaw Stopped While Cutting A Heavy Load. I Can't Get It To Start Again. I

Current Answers

Answer #1: Posted by nanzy on July 13th, 2021 8:16 AM

Answer #2: Posted by SonuKumar on July 13th, 2021 8:59 AM

https://www.youtube.com/watch?v=tLnIM3TTMYM&t=29s

https://www.youtube.com/watch?v=tLnIM3TTMYM&t=106s

https://www.youtube.com/watch?v=tLnIM3TTMYM&t=123s

https://www.youtube.com/watch?v=tLnIM3TTMYM&t=149s

https://www.youtube.com/watch?v=tLnIM3TTMYM&t=175s

Try this steps below first, then analysis the issue and act as per youtube video above

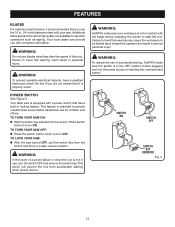

Do Ryobi table saws have a reset button?

Push the reset button then turn the saw on. center. when power returns. the blade before operating the switch to start the tool.

Why wont my Ryobi table saw turn on?

A failed power supply, broken on/off switch, bad motor overload, broken power cord or failed drive motor can prevent the table saw motor from starting. First, try resetting the overload. If the table saw motor won't start after resetting the overload, then the saw may not be getting power from the electrical outlet.

How do you reset a table saw overload?

The table saw motor overload shuts off electrical power to the motor to protect the motor if it overloads or overheats. After the motor cools down, pressing the reset switch on the motor overload restores power to the motor circuit. Replace the motor overload if it won't reset or false trips.

How do I know if my table saw motor is bad?

The first place to look for a problem when a table saw won't start is the power cord, especially if the saw is portable, because the plug may be loose. If pressing the red reset on the motor -- which is a thermal overload switch -- doesn't restore operation, then the breaker may have tripped

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Ryobi RTS10 Manual Pages

Similar Questions

why does my ryobi model p2102 blower start for a second and then stop? I have tried several differen...

I was recently given this table saw. Well shortly after turning it on the saw will make a sound and ...

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting...