Ryobi DP102L Support Question

Find answers below for this question about Ryobi DP102L.Need a Ryobi DP102L manual? We have 4 online manuals for this item!

Question posted by chief4070 on December 29th, 2011

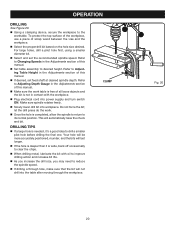

Dp102l Quit Working

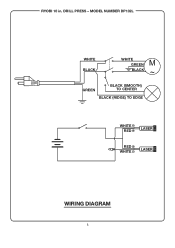

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting that is set up when you take it out of the box...half way during the operation the drill press stopped...I do modification on PC cases. Did I burned out the motor by putting such a heavy load when drilling?

Current Answers

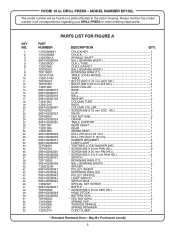

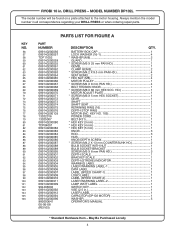

Related Ryobi DP102L Manual Pages

Similar Questions

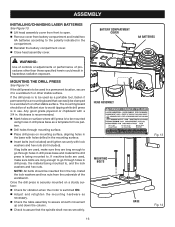

Ryobi Drill Press Lazer Not Working Brand New

my laser not working brand new and batteries is fitted

my laser not working brand new and batteries is fitted

(Posted by johanwessels06 1 year ago)

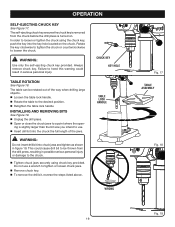

Machine Is Not Turning On When Inserting Key And Pushing Up Key Pops Out?

(Posted by estherflam 2 years ago)

My Ryobi Battery Powered Gun Just Quit Working Altogether. No Light, Not A Sound

how do I fix it? It just went completely dead. I fully charged battery and still nothing

how do I fix it? It just went completely dead. I fully charged battery and still nothing

(Posted by Dvlpr3 3 years ago)

Ryobi Grinder Suddenly Quit Working ... ?

I was using the grinder when the wheel caught on a sharp angle of the work piece and the grinder sud...

I was using the grinder when the wheel caught on a sharp angle of the work piece and the grinder sud...

(Posted by ellisted60 9 years ago)

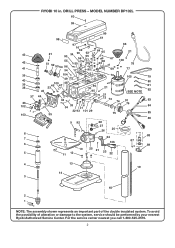

How To Replace A Depth Stop Ring On The Dp102l What Parts Are Needed

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to...

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to...

(Posted by rjbsilverking 10 years ago)