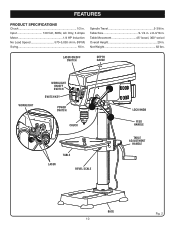

Ryobi DP102L Support Question

Find answers below for this question about Ryobi DP102L.Need a Ryobi DP102L manual? We have 4 online manuals for this item!

Question posted by Anonymous-67549 on July 20th, 2012

What Size Is The Sleeve

The person who posted this question about this Ryobi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

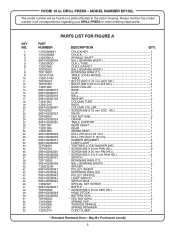

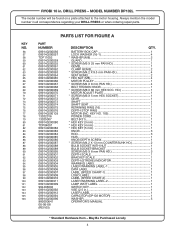

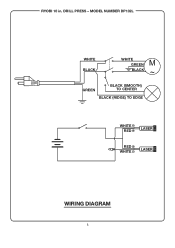

Related Ryobi DP102L Manual Pages

Similar Questions

Is P213 The One I Want For My Dp102l Drill Press

ok im looking for a manual for my DP102L RYOBI 10 inch drill press, and I want to know if the P213 w...

ok im looking for a manual for my DP102L RYOBI 10 inch drill press, and I want to know if the P213 w...

(Posted by martinb4 8 years ago)

Dado Blade Size

What size dado blade can or should you use on a RTS10?

What size dado blade can or should you use on a RTS10?

(Posted by acates11 9 years ago)

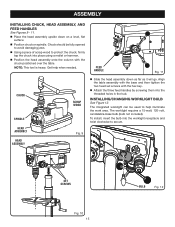

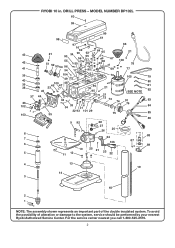

How To Replace A Depth Stop Ring On The Dp102l What Parts Are Needed

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to...

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to...

(Posted by rjbsilverking 10 years ago)

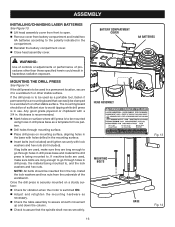

Dp102l Quit Working

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting...

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting...

(Posted by chief4070 12 years ago)