Ryobi DP102L Support Question

Find answers below for this question about Ryobi DP102L.Need a Ryobi DP102L manual? We have 4 online manuals for this item!

Question posted by stantonal64 on December 27th, 2013

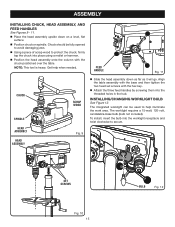

Positioning Of Laser

The X is too far back on the table. How can I adjust that?

Current Answers

Answer #1: Posted by hzplj9 on December 29th, 2013 1:53 PM

You can adjust the laser by reading page 15 of the installation manual downloadable from the Helpowl site via this link.

http://www.manualowl.com/m/Ryobi/DP102L/Manual/202282?page=1

Related Ryobi DP102L Manual Pages

Similar Questions

Ryobi 10" Table Saw Dado Throat Plate

where can I find a dado throat plate for the Ryobi 10" table saw?

where can I find a dado throat plate for the Ryobi 10" table saw?

(Posted by Rick52757 2 years ago)

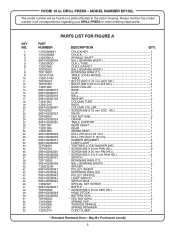

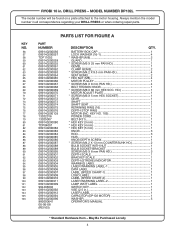

How To Replace A Depth Stop Ring On The Dp102l What Parts Are Needed

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to...

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to...

(Posted by rjbsilverking 10 years ago)

Where Are The Positive Stops Inside The Cabinet? Need To Make Adjustments For

I need to make adjustments for a 90 degree cut.

I need to make adjustments for a 90 degree cut.

(Posted by rnicot 10 years ago)

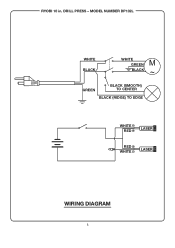

Dp102l Quit Working

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting...

Using a 4 1/2 inch bimetal hole saw to drill thru a side panel of my PC case using the speed setting...

(Posted by chief4070 12 years ago)