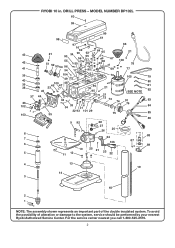

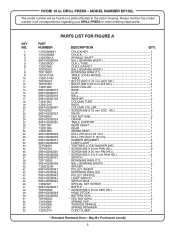

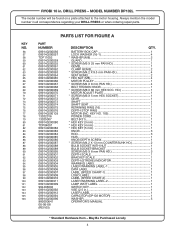

Ryobi DP102L Support Question

Find answers below for this question about Ryobi DP102L.Need a Ryobi DP102L manual? We have 4 online manuals for this item!

Question posted by dannylandrum on February 21st, 2019

Pulley Insert

Current Answers

Answer #1: Posted by Odin on February 21st, 2019 4:50 PM

[use the contact information at:

https://www.contacthelp.com/ryobi/customer-service], request a part number. Then (with a part number if possible) try

- https://encompass.com/

- a search engine like Google's or Yahoo's

- http://www.searchtempest.com/, which displays global listings from eBay, Craigslist, and other sources

(For option 3, you may want to use a free tracking program like https://www.followthatpage.com/ to save you from having to repeat your search over time.)

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

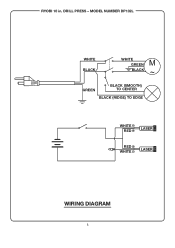

Related Ryobi DP102L Manual Pages

Similar Questions

the schematic shows a 1 inch X 20 nut 1 inch is way too la

This happens even after adjusting the motor for different tension levels. It will run maybe 20/30 se...

ok im looking for a manual for my DP102L RYOBI 10 inch drill press, and I want to know if the P213 w...

I bought a DP102L at a auction but the entire depth stop feature was missing what parts do I need to...