Pfaff hobbymatic Support Question

Find answers below for this question about Pfaff hobbymatic.Need a Pfaff hobbymatic manual? We have 2 online manuals for this item!

Question posted by carmit on December 11th, 2017

Turning The Flywheel Is Very Stiff When Lifting The Needle. There Is A High- Pi

Current Answers

Answer #1: Posted by BusterDoogen on December 11th, 2017 5:23 PM

1. Do not put oil on the motor or near any of the belts. This will cause slipping and you will have no power. Also old motors can spark so keep the oil away.

2. You are allowed to unscrew the top plate and the bottom plate. You can take off the plate that the presser foot rests on and look in the feed dogs that come up through that plate to see if there is any lint build up down there. Visually inspect for thread build up. The best way to handle this is by blowing out the whole mechanism with an air compressor or a can of air. This will delint the machine and expose any bound threads.

3. Change the needle and check to make sure needle is in correctly. Take out the bobbin case and look for lint inside the bobbin case. after this is out, go get machine oil from Home Depot or Lowe's. I prefer Tri-flow. Avoid WD-40 and penetrating oils as these will remove the good grease instead of re-lubricating the machine. You will run the machine spraying all visible moving parts and eventually you will hear a reduction in noise. Stay away from motor again as you do this. Now the open top is sprayed, the needle holding bar and surrounding mechanism is sprayed. The hook and the mechanism that holds the bobbin case should be sprayed. Also, spray the mechanical parts beneath the machine.

4. Use a can of compressed air and blow out excess oil. Make sure tension springs and anywhere thread runs is free of lint. Blow hard on the upper tension spring.

5. Because you have not touched any tension screws you should be able to reassemble and start sewing where you left off.

6. Don't be afraid to take the plates off the machine and clean and oil, you wont hurt your machine and if you get into a bind the sewing store can usually help.

7. Re-assemble

I hope this is helpful to you!

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful. Please feel free to submit further info for your question, if a solution was not provided. I appreciate the opportunity to serve you!

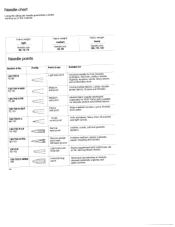

Related Pfaff hobbymatic Manual Pages

Similar Questions

The overlocker works well but has developed a high pitched screech scraping sound when it starts up ...

is there a sleeve to extend the sewing platform for the 807?

I can not sew because I can not lift the needle. The wheel can not turn, only the inner whhel turns....

The upper presser foot on my Pfaff Hobbymatic 935 will not lower completely. I lowered the arm but t...

I have pushed empty bobbin into place against P, held the hand wheel steady and turned kno 106 towar...