Harbor Freight Tools 61454 Support Question

Find answers below for this question about Harbor Freight Tools 61454 - 21 gal. 2.5 HP 125 PSI Cast Iron Vertical Air Compressor.Need a Harbor Freight Tools 61454 manual? We have 1 online manual for this item!

Question posted by Hamilton2007 on January 8th, 2016

Central Air Compressor Model 61454

can a start valve be repaired? I found that after the unit builds up to pressure then when used it will not restart but if a push the little tip on the start valve it kicks in

Current Answers

Answer #1: Posted by TommyKervz on January 24th, 2016 2:55 AM

Yes please call 1-800-423-2567, 24 hours a day/7 days a week. to place your order for the rplacement, please specify the product name and sku/item number as well as the quantity of each item you are ordering. Please have any flyers or coupons readily available. or go here to request service assistance.

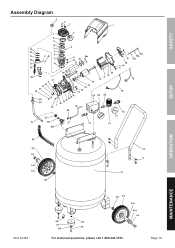

Related Harbor Freight Tools 61454 Manual Pages

Similar Questions

I Need An Unloader Tube For Air Compressor Serial #61693

I need an unloader tube for a central pneumatic air compressor serial number 61693

I need an unloader tube for a central pneumatic air compressor serial number 61693

(Posted by josephelliscox 1 year ago)

Why Does Oil Comes Out Of Oilvfill Cap?

(Posted by rarce509 2 years ago)

Harbor Freight Air Compressor Model 69667

Need 3 gaskets and a thin V shape that's goes under the reed valve plate , who sells parts

Need 3 gaskets and a thin V shape that's goes under the reed valve plate , who sells parts

(Posted by absolutetruckers40 7 years ago)