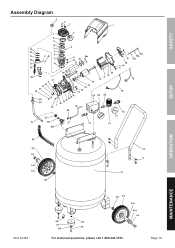

Harbor Freight Tools 61454 Support Question

Find answers below for this question about Harbor Freight Tools 61454 - 21 gal. 2.5 HP 125 PSI Cast Iron Vertical Air Compressor.Need a Harbor Freight Tools 61454 manual? We have 1 online manual for this item!

Question posted by rarce509 on October 29th, 2021

Why Does Oil Comes Out Of Oilvfill Cap?

Requests for more information

Why is oil coming out of oil fill cap

Current Answers

Answer #1: Posted by SonuKumar on October 29th, 2021 9:58 PM

Restricted intake - Oily discharge is often caused by restrictions on the compressor's air intake. In cases such as these, the air filters either need to be cleaned or replaced altogether. ... Overfilled oil tank - If the compressor has too much oil, some of that excess can seep into the discharge.2

What happens if you put too much oil in air compressor?

However, filling your compressors oil sump to the top can cause significant internal damage to your unit. When excess amounts of oil become aerosolized by the compressor's discharge, it can cause damages not only to your compressor, but to any pneumatic tools and accessories that are hooked up to your compressor.

https://www.youtube.com/watch?v=pduPuJ9k9Bw

https://www.youtube.com/watch?v=kfCPC4k-8V0

https://manuals.harborfreight.com/manuals/61000-61999/61454.pdf

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Harbor Freight Tools 61454 Manual Pages

Similar Questions

can some one tell where i can get a rear compressor oil seal for this 2.5 hp 21 gal compressor and a...

Where is the oil breather plug located. I just bought my first compressor model 69667