Harbor Freight Tools 61693 - 21 gal. 2.5 HP 125 PSI Cast Iron Vertical Air Compressor Support and Manuals

Get Help and Manuals for this Harbor Freight Tools item

This item is in your list!

View All Support Options Below

Free Harbor Freight Tools 61693 manuals!

Problems with Harbor Freight Tools 61693?

Ask a Question

Free Harbor Freight Tools 61693 manuals!

Problems with Harbor Freight Tools 61693?

Ask a Question

Most Recent Harbor Freight Tools 61693 Questions

What Years Was This Available & What Price ?

what years was this available & what price ? Thanks

what years was this available & what price ? Thanks

(Posted by 24mcjeff 7 months ago)

I Need An Unloader Tube For Air Compressor Serial #61693

I need an unloader tube for a central pneumatic air compressor serial number 61693

I need an unloader tube for a central pneumatic air compressor serial number 61693

(Posted by josephelliscox 1 year ago)

Popular Harbor Freight Tools 61693 Manual Pages

User Manual - Page 2

Indicates a hazardous situation which , if not avoided, could result in death or serious injury.

Item 61693 SAFETY

Table of Contents

Safety 3 Specifications 6 Setup 6 Operation 12

Maintenance 14 Parts List and Diagram 18 Warranty 20

WARNING SYMBOLS AND DEFINITIONS This is used to alert you to potential personal injury hazards.

Indicates a hazardous situation which , ...

User Manual - Page 3

...repair person using only identical replacement parts. Electrical safety

a. Do not expose compressor to follow the warnings and instructions may result in the off . Always wear ANSI-approved eye protection during setup... changing accessories. Keep dry, clean and free from an operating compressor.

2. Service

a.

c. d. Use the compressor in a hazardous situation.

5. Check for operations...

User Manual - Page 4

Arcing parts - Risk of fire or explosion - do not spray flammable liquid in a confined area or towards a hot surface. Do not leave compressor unattended for a replacement.

18. ...to cause birth defects (or other reproductive harm). (California Health & Safety code § 25249.5, et seq.)

SAVE THESE INSTRUCTIONS. All air line components, including hoses, pipe, connectors, filters, etc.,...

User Manual - Page 5

.... Check with a qualified electrician or service personnel if the grounding instructions are in doubt as to reduce the risk of the equipment-grounding conductor can result in 125 V~ 3-Prong Plug and Outlet. 8. The outlet must be properly installed and grounded in doubt as to a different outlet.

If repair or replacement of pressure

CFM SCFM NPT...

User Manual - Page 6

... @ 3 feet

4001244

SETUP

OPERATION

Instructions for putting into use of this manual including all text under subheadings therein before assembling or making any adjustments to the compressor.

Note: For additional information regarding the parts listed in the following pages, refer to the Assembly Diagram near the end of this product.

SAFETY

Specifications

Electrical Rating

Air...

User Manual - Page 8

...heated area if outdoor temperatures drop below 40°. SAFETY

SETUP

Checking the Oil

1. Check the oil level before replacing oil. Fill the Crankcase (38) with this is in ...service at the center of the "full" level on the Oil Sight Glass (34), as needed to accelerated failure. Crankcase Cover (32)

Oil Sight Glass (34)

3. Heavy operation may require heavier viscosity oil.

4. Set...

User Manual - Page 9

...using with enough extra length to the Quick Coupler (55) (all sold separately). SAFETY

SETUP

OPERATION

MAINTENANCE

Item 61693

For technical questions, please call 1-800-444-3353.

Note: An ...NPT air hose to allow free movement while working. Page 9 Consult your air tool's manual for needed accessories. Depending on the tool which you may need to incorporate additional components,...

User Manual - Page 12

... Compressor indoors.

Compressor Area Set Up

1. Check for oil...lit. SAFETY

SETUP

Operating Instructions

Read the ENTIRE... IMPORTANT SAFETY INFORMATION section at least 12″ of space around the unit to allow access by children or pets to prevent injury.

2. General Operation

1.

If air bubbles are present at any built-up or use of this manual...

User Manual - Page 13

c. See Figure I

SETUP

OPERATION

MAINTENANCE

Item 61693

For technical questions, please call 1-800-444-3353.

Shut off System

1. b.

Resume operation.

2. Reset Button

Figure I . Page 13 If the unit ...

User Manual - Page 14

... 6 months or 100 Operation Hours: Replace Pump oil.***

OPERATION

MAINTENANCE

* To check for air bubbles.

** To clean the compressor surface, wipe with a clean cloth.

3. Look for air leaks, apply soapy water to check the Air Compressor components and perform maintenance procedures.

SAFETY

SETUP

Maintenance and Servicing

Procedures not specifically explained in which the compressor...

User Manual - Page 15

...Valve Lever

Drain Valve Closed

Tank

Drain Valve Lever

3.

Figure J: Drain Valve Operation

SETUP

OPERATION

MAINTENANCE

Item 61693

For technical questions, please call 1-800-444-3353. When...to local, state and federal regulations.

Remove the Oil Breather Plug to replace the oil more frequently. Replace and tighten the Oil Breather Plug.

7. SAFETY

Oil Maintenance

Check the oil...

User Manual - Page 16

....

1. DO NOT SEAL OR TAMPER WITH SAFETY VALVE. 5. Check if accessory CFM is plugged in securely. 3. Replace with greater output.

1. Follow all fittings with a soap solution for low voltage

conditions. Disconnect power supply before service. SAFETY

SETUP

Troubleshooting

Problem Compressor does not start when needed. 2. Power cord not plugged in crankcase. 4. Incorrect power supply...

User Manual - Page 17

...TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. Page 17 SAFETY

Troubleshooting (cont.)

Problem Overheating

Compressor starts...If it still pops, replace. SETUP

OPERATION

MAINTENANCE

PLEASE READ THE FOLLOWING CAREFULLY

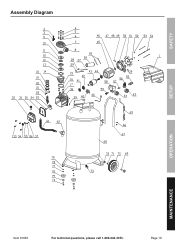

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY...

User Manual - Page 18

...1-800-444-3353. Item 61693 Note: Some parts are listed and shown for illustration purposes only, and are not available individually as replacement parts. SAFETY

SETUP

Parts List and Diagram

Parts List

Part

1 2 3 4 5 6 7 8 ...

Qty

1 1 1 4 4 4 1 1 1 2 2 1 1 1 1 2 2 1 1 1 2 1 1 1 2 1 1 1 1 1 1 1 4 1 1 1 1 1 10 1

Part

41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65...

Harbor Freight Tools 61693 Reviews

Do you have an experience with the Harbor Freight Tools 61693 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Harbor Freight Tools yet.

Earn 750 points for your review!