Harbor Freight Tools 34706 - 12'' x 33-3/8'' Wood Lathe Support and Manuals

Get Help and Manuals for this Harbor Freight Tools item

This item is in your list!

View All Support Options Below

Free Harbor Freight Tools 34706 manuals!

Problems with Harbor Freight Tools 34706?

Ask a Question

Free Harbor Freight Tools 34706 manuals!

Problems with Harbor Freight Tools 34706?

Ask a Question

Most Recent Harbor Freight Tools 34706 Questions

Popular Harbor Freight Tools 34706 Manual Pages

User Manual - Page 2

... 9 12 13

14

I . Technical data

VARIABLE SPEED WOOD LATHE

MODEL NUMBER

T34706

MOTOR SPEEDS SWITCH DISTANCE BETWEEN CENTERS SWING OVER BED DRIVE ...RIGHT HAND THREAD 3/8" 3/8" 2-1/4" SPUR CENTER - Table of contents

SECTION

I . Electrical information V. Operation IX. Specific safety rules for the wood lathe IV. MORSE #2 TAPER BALL BEARING CENTER - General safety rules III. Assembly ...

User Manual - Page 3

... CONDITIONS. Make sure that are removed from the electrical outlet when making adjustments, changing parts, cleaning or working on floor surfaces that the power switch is accidentally hit. Serious ...it was not designed.

7.

ALWAYS MAKE SURE all tools are slippery with this entire instruction manual. Turn the power switch to a complete stop.

13. DO NOT FORCE THE ...

User Manual - Page 4

... PROTECTION. ALWAYS wear safety goggles (not glasses).

Follow instructions for alignment of moving parts, binding of moving parts, breakage of parts, improper mounting or any drugs, alcohol or medication that... properly.

19.WARNING: Dust generated from certain materials can be properly repaired or replaced before use.

17. Use dust collection systems whenever possible. Ordinary eyeglasses...

User Manual - Page 5

...the turning tools to the wood lathe.

8. For your own safety, read the entire instruction manual before operating.

5. Read the warning label attached to bite into the wood. Always ...thrown out of stock.

12. Specific safety rules for the wood lathe

WARNING: DO NOT OPERATE YOUR WOOD LATHE UNTIL IT IS COMPLETELY

ASSEMBLED AND INSTALLED ACCORDING TO THE INSTRUCTIONS. 1. Do not mount a...

User Manual - Page 6

...is equipped with ALL local codes and ordinances. If it ...installed by a qualified electrician. Always make safety come to select them from the lathe.

If repair or replacement of the electric cord or plug is necessary, DO NOT connect the equipment grounding conductor to reduce the risk of least resistance for the wood .lathe Continued

16. Electrical information

GROUNDING INSTRUCTIONS...

User Manual - Page 7

... as the current stamped on the motor nameplate. When using an extension cord, be protected with a 15 Amp time lag fuse. Always replace a damaged extension cord or have it repaired by a qualified person before using 120 volts only)

Ampere Rating

Total length of power and overheating. Use a separate electrical circuit for your...

User Manual - Page 9

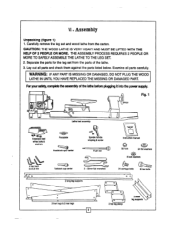

... TO SAFELY ASSEMBLE THE LATHE TO THE LEG SET. 2. VI . Lay out all parts carefully. Examine all parts and check them against the parts listed below.

Fig. 1

ld

LJ\

Lathe bed assembly

(I Extension bed w/hex bolts & washers

4 hex keys 3.4,8,8 mm

o a

Faceplate

.c:0 tri'

Spindle handle w/spring & screw

Instruction manual

Headstock spur center

Push rod

Tailstock cup center...

User Manual - Page 10

... the

top plate and align the holes in the bed [3]

with other lathe parts or the workpiece.To operate, push the handle lever in each bed and into... washers [4], and nuts [5]. 2. Repeat step 1 for the opposite side. 4. Attach short supports [7] to the

outside edge of the way.

4 0

2 3 1

1

Fig. 4

Set the

headstock down carefully.

3

4. Thread washer [6] and nut [7] onto bolt [5], and ...

User Manual - Page 11

... separate the faceplate from the spindle. 2. Fig. 8

I

3

6 4 Fig. 7

5 4 2 3

WARNING: DO NOT OPERATE YOUR WOOD LATHE UNTIL IT IS COMPLETELY

ASSEMBLED AND ADJUSTED ACCORDING TO THE INSTRUCTIONS.

11

To remove either the headstock spur or the tailstock center, insert the push-out rod [5] into the hole [6] at the opposite end of the...

User Manual - Page 12

...WARNING: DO NOT TURN THE HEADSTOCK ASSEMBLY MORE THAN 180° CLOCKWISE FROM THE SPINDLE SETTING POSITION OR DAMAGE TO WIRING MAY OCCUR.

0 a

DO NOT TURN THE HEADSTOCK ASSEMBLY ...the lock handle [1]. Pull out the headstock release [2]. The headstock has 5 preset positions.

• 0° setting for all spindle turning applications.

• 60° / 90° / 120° for use when ...

User Manual - Page 13

... the switch

housing.

Opp

L

3 Fig. 15 4 1 2 Store it has

come to the lowest speed setting before operating lathe.

3. Fig. 13 2

Fig. 14

Tailstock (Figure 15)

1. You can extend up to...2. Turn the lever clockwise to increase the speed and counterclockwise to choose lathe speed.

3. To set the speed, pull back on the bed. Lock levers [4] and [2]

before turning the switch...

User Manual - Page 14

...MAINTENANCE OR LUBRICATION WORK ON THE LATHE.

. Periodic lubrication of the spring levers and other threaded parts will help keep the surface clean and the movement of automotive wax applied to the bed will... make the necessary

adjustments using the arm [21, make these parts easier to the right or left and back or front. VI. Tighten the lever [4] when ...

User Manual - Page 16

...MOTOR ANGULAR SETTING ASSEMBLY

1 MK 1 M65. 1 M66. 3

LOGO LABEL WARNING LABEL SPEED LABLE

M36.

STAND LONG CROSS SUPPORT

1 M54-5. STAND SHORT-CROSS SUPPORT

2

M24....

TOOL REST BODY

1

1 IWO.

PULLEY-SPINDLE (RIGHT)

M13• V-BELT M23

M14. MEDIUM WOODWORKING LATHE PARTS LIST

INDEX NO PARTS DESCRIPTION Q'TY 'INDEX NO PARTS...

User Manual - Page 17

...this warranty , the product or part nos? Proof

of purchase date and an explanation of the complaint must bear the cost of retuning the product.

4

This warranty gives you specific legal rights and you . Pt,...warrants to you may also have other parts and components of our product. If Gilt inspWioa vedites the

defect, we will either repair or replace the product at our expense,but ...

User Manual - Page 18

... AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE

UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER, THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THER IO, OR

ARISING OW OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Harbor Freight Tools 34706 Reviews

Do you have an experience with the Harbor Freight Tools 34706 that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Harbor Freight Tools yet.

Earn 750 points for your review!