Harbor Freight Tools 69667 Support Question

Find answers below for this question about Harbor Freight Tools 69667 - 8 gal. 2 HP 125 PSI Oil Lube Air Compressor.Need a Harbor Freight Tools 69667 manual? We have 1 online manual for this item!

Question posted by absolutetruckers40 on June 14th, 2016

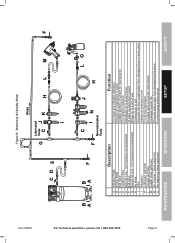

Harbor Freight Air Compressor Model 69667

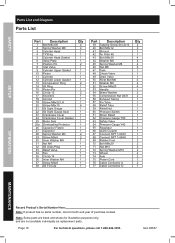

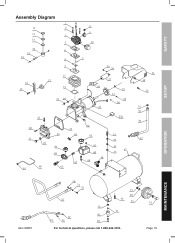

Need 3 gaskets and a thin V shape that's goes under the reed valve plate , who sells parts

Current Answers

Related Harbor Freight Tools 69667 Manual Pages

Similar Questions

Do You Need To Oil A 12' Disk Sander From Harbor Freight Central Machine Model

(Posted by joenelson5770 5 months ago)

Need A Parts List For Harbor Freight Item#62519?

How can I get a Parts list for the harbor freight Item#62519. Can you send it to may email: jrcolt91...

How can I get a Parts list for the harbor freight Item#62519. Can you send it to may email: jrcolt91...

(Posted by jrcolt911 3 years ago)

69667 Reed Valve

I need to replace a broken reed valve on the 69667 central pneumatic air compressor. I can't seem to...

I need to replace a broken reed valve on the 69667 central pneumatic air compressor. I can't seem to...

(Posted by CraigPetraszewsky 6 years ago)

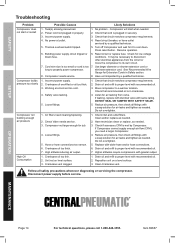

For The Break In Procedure, Do I Have To Open Up The Safety Valve?

I just bought a 69667 and want to follow the break in process listed in page 7. It asks that you ope...

I just bought a 69667 and want to follow the break in process listed in page 7. It asks that you ope...

(Posted by gonzalobriceno 8 years ago)

Oil Breather Plug

Where is the oil breather plug located. I just bought my first compressor model 69667

Where is the oil breather plug located. I just bought my first compressor model 69667

(Posted by dougnnai 8 years ago)