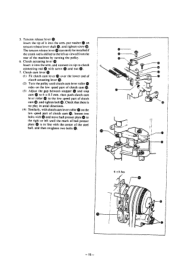

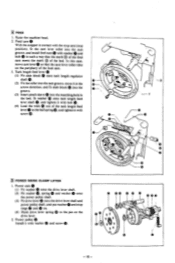

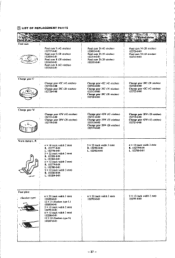

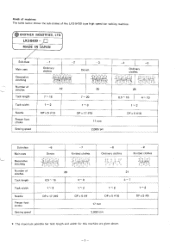

Brother International LK3-B430 Support Question

Find answers below for this question about Brother International LK3-B430.Need a Brother International LK3-B430 manual? We have 2 online manuals for this item!

Question posted by info42861 on February 11th, 2022

La Máquina De Hacer Presillas No Me Corta El Hilo.

La máquina de presillas no me corta el hilo.,

Current Answers

Answer #1: Posted by SonuKumar on February 12th, 2022 9:45 AM

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Brother International LK3-B430 Manual Pages

Similar Questions

Ha Ocurrido Un Fallo. Apague La Máquina Y Vuelva A Encenderla

La máquina trabajo bien ayer y hoy al encenderla me da este mensaje. Que puedo hacer?

La máquina trabajo bien ayer y hoy al encenderla me da este mensaje. Que puedo hacer?

(Posted by leonelmendozagt 2 years ago)

Mi Brother Ke 430d Presenta Error 150 Y No Aparece En El Manual No Se Que Hacer.

mi maquina depronto presento depronto presento el error 150 y ese error no aparece en el manual que ...

mi maquina depronto presento depronto presento el error 150 y ese error no aparece en el manual que ...

(Posted by edgardomoralesbarrios59 4 years ago)

Causas Por Las Que No Enciende La Maquina ??

Electricidad OK Cable OK Cual podria ser otro motivo que no encienda la maquina. Brother Cs-6000i

Electricidad OK Cable OK Cual podria ser otro motivo que no encienda la maquina. Brother Cs-6000i

(Posted by ccastillo4u 9 years ago)

How To Adjust La 2125 Electrical Voltage For India?

I have a Brother LA 2125 sewing machine bought in the U.S and now with me in India. How do I adjust ...

I have a Brother LA 2125 sewing machine bought in the U.S and now with me in India. How do I adjust ...

(Posted by jakes7027 9 years ago)

Where Can I Take A Class For Xl Project Runway 5500 In Las Vegas Nv

(Posted by paulinetween 12 years ago)