Brother International LK3-B430 Support Question

Find answers below for this question about Brother International LK3-B430.Need a Brother International LK3-B430 manual? We have 2 online manuals for this item!

Question posted by nelhera141 on December 16th, 2013

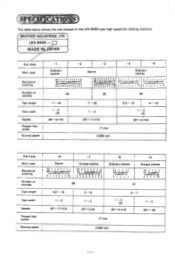

Brother Lk3-b430 It Is Not Switching To High Speed To Operate Properly

The person who posted this question about this Brother International product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Brother International LK3-B430 Manual Pages

Similar Questions

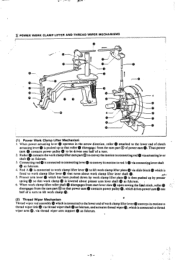

La Máquina De Hacer Presillas No Me Corta El Hilo.

La máquina de presillas no me corta el hilo.,

La máquina de presillas no me corta el hilo.,

(Posted by info42861 2 years ago)

Brother Sewing Machine Representative In Hyderabad - India

Can some one let me know if brother sewing machine has an office or representative / deler in Hydera...

Can some one let me know if brother sewing machine has an office or representative / deler in Hydera...

(Posted by jakes7027 9 years ago)

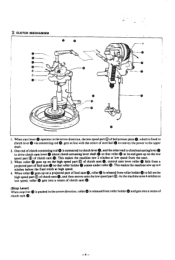

Why Is My Machine Lk3 B430-2 Is In Continus Sikle How Can I Vorrect It

(Posted by Frizschulz 10 years ago)

Brother Pc-420 Prw Limited Edition Project Runway Sewing Machine Will Not

thread needle

thread needle

(Posted by graphevaru 10 years ago)

Spare Parts

i have a sewing machine number LK3-B430-2, and the power pulley assembly is damaged. the serial numb...

i have a sewing machine number LK3-B430-2, and the power pulley assembly is damaged. the serial numb...

(Posted by michelelhajj 10 years ago)