Brother International LK3-B430 Support Question

Find answers below for this question about Brother International LK3-B430.Need a Brother International LK3-B430 manual? We have 2 online manuals for this item!

Question posted by michelelhajj on October 11th, 2013

Spare Parts

i have a sewing machine number LK3-B430-2, and the power pulley assembly is damaged. the serial number of the part is 151930201. if you have a spare part , please contact me on my email address.

Best regards.

Current Answers

Related Brother International LK3-B430 Manual Pages

Similar Questions

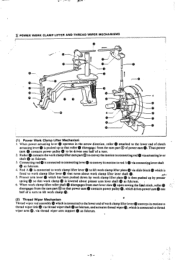

La Máquina De Hacer Presillas No Me Corta El Hilo.

La máquina de presillas no me corta el hilo.,

La máquina de presillas no me corta el hilo.,

(Posted by info42861 2 years ago)

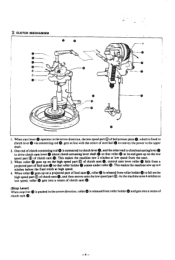

Why Is My Machine Lk3 B430-2 Is In Continus Sikle How Can I Vorrect It

(Posted by Frizschulz 10 years ago)

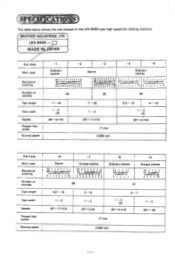

Brother Lk3-b430 It Is Not Switching To High Speed To Operate Properly

(Posted by nelhera141 10 years ago)

Can't Get My Machine To Do Anything Beyond Powering Up.....

I have this machine. It will power up but I can't get it to do anything else. Thought I would ask yo...

I have this machine. It will power up but I can't get it to do anything else. Thought I would ask yo...

(Posted by haneycl 13 years ago)