Ryobi A25RT02G Support and Manuals

Get Help and Manuals for this Ryobi item

This item is in your list!

View All Support Options Below

Free Ryobi A25RT02G manuals!

Problems with Ryobi A25RT02G?

Ask a Question

Free Ryobi A25RT02G manuals!

Problems with Ryobi A25RT02G?

Ask a Question

Popular Ryobi A25RT02G Manual Pages

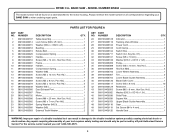

Repair Sheet - Page 3

... Guide Assembly...Set Screw (M4 x 4 mm 1 Handle Seat 1

WARNING: Improper repair of your BAND SAW or when ordering repair parts. BAND SAW - RYOBI 9 in all correspondence regarding your tool requires safety testing and should only be found on a label attached to the double insulation system possibly causing electrical shock or electrocution. Always mention the model number in . Table...

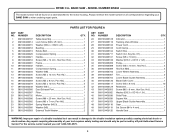

Repair Sheet - Page 4

...Label 1 Blade Order Label 1 Height Lock Label 1 Operator's Manual

WARNING: Improper repair of your BAND SAW or when ordering repair parts. For the service center nearest you call 1-800-525-2579.

4

Hd 1

... 990000198 11-19-12 (Rev:01)

DESCRIPTION

QTY. MODEL NUMBER BS904

The model number will be performed by a Ryobi Authorized Service Center. x 6 mm x 0.3t 1

Miter Gauge...

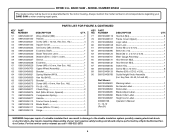

Repair Sheet - Page 6

... repairs requiring disassembly of a double insulated tool can result in all correspondence regarding your tool requires safety testing and should only be found on a label attached to the double insulation system possibly causing electrical shock or electrocution. PARTS LIST FOR FIGURE B

KEY PART NO. MODEL NUMBER BS904

The model number will be performed by a Ryobi Authorized Service...

User Manual - Page 4

... SET. Instructions for and remove all adjustments are included with saw table. To avoid accidental blade contact, minimize

blade breakage, and provide maximum blade support, always adjust the blade guide assembly to avoid accidental starting a cut , be made by an authorized service center.

Before making contact with the accessory.

DOUBLE CHECK ALL SETUPS...

User Manual - Page 5

... saw .

Your risk from these exposures varies, depending on how often you check and adjust blade guide settings before first use them these chemicals are functional for some dust created by an authorized service center to avoid risk.

SAVE THESE INSTRUCTIONS. We recommend that you do this type of the blade tension,

blade...

User Manual - Page 9

...set.

Do not discard the packing material until you have carefully inspected and satisfactorily operated the tool.

If any parts... Loose Parts List are replaced.

Failure...Table 1

B Miter Gauge 1

C Hex key, 2 mm 1

D Hex key, 4 mm 1

E Washer 1

F Table Lock Lever 1

Operator's Manual... a firm supporting surface such ... and require customer installation. NOTE: This ...

User Manual - Page 11

...problem.

OPERATION

WARNING:

Do not allow the blade to cut.

The smallest diameter circle that a careless fraction of your saw table...this operator's manual. Do not...Guide Support and Thrust Bearings procedures explained in the adjustments section of wood and wood composition products

Various straight line cutting operations in serious personal injury.

These settings...

User Manual - Page 12

... saw table, that the blade guides, thrust bearings, and blade tension are properly adjusted, that no parts have a tendency to curve in a safe place.

Unplug the saw blade using the RAPID SET blade... during a cut ). Workpieces must lay flat on the saw to the support surface to be cut off the saw table before following the pattern line as dowel rods or tubing because they have ...

User Manual - Page 13

... length. Failure to unlock the blade

guide assembly. INSTALLING AND ADJUSTING THE BLADE

See Figure 16...table. Open the front covers by pulling the left of blade tension, blade tracking, blade guides, and thrust bearings. If the new blade was oiled to be turned inside out if the teeth are pointing so the rag does not catch on the rubber tires.

Re-engage the RAPID SET...

User Manual - Page 14

... the thrust bearings when you are about the thickness of the blade guide assembly. It is installed. Tighten set screw and remove dollar bill. Rotate, by hand, a full three rotations to set

screws using hex keys. Slide the upper blade guide support on the band saw blade is within 1/64 in place before turning...

User Manual - Page 16

... sections, Adjusting

Thrust Bearings and Blade Guide

Support. mate center of the upper wheel.

1. guides and bearings. Blade guides will not cut straight.

1.

Blade will not stay in position. 1. Motor defective.

2. Tighten blade guide screws securely. Replace blade. Saw is binding.

3. TROUBLESHOOTING

Problem Cause Solution

Motor will not run in...

User Manual 3 - Page 3

... 1 Upper Blade Guide Assembly 1 Gear 1 Set Screw (M4 x 4 mm 1 Guide Height Adjustment Bracket 1

WARNING: Improper repair of your BAND SAW or when ordering repair parts. Key No. ...Guide Assembly 1 Blade Safe Cover 1 Screw (M4 x 8 mm 10 Restrainer 1 Screw (M6 × 8 mm, Hex Soc. MODEL NUMBER BS904G

The model number will be performed by a Ryobi Authorized Service Center.

Any repairs...

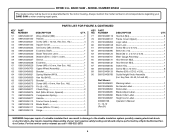

User Manual 3 - Page 4

...Set Screw (M5 x 6 mm 1

Eccentric Shaft 1

Blade Tensioner Lever 1

Wave Washer (ID16 × OD21 x 0.3t 1

Tension Lever Mount 1

Eccentric 1

Screw (M6 x 16 mm, Hex Soc. MODEL NUMBER BS904G

The model number will be performed by a Ryobi Authorized Service...Height Lock Label 1 Operator's Manual

WARNING: Improper repair of your BAND SAW or when ordering repair parts. BAND SAW - Wavy ...

User Manual 3 - Page 6

... the double insulation system possibly causing electrical shock or electrocution. MODEL NUMBER BS904G

The model number will be performed by a Ryobi Authorized Service Center.

For the service center nearest you call 1-800-525-2579.

6 Hd 4

WARNING: Improper repair of your BAND SAW or when ordering repair parts. Any repairs requiring disassembly of a double insulated tool can result in...

User Manual 3 - Page 8

... Retaining Ring 2 7 089120406090 Shaft 1 8 089120406091 Pulley 1 9 089120406093 Blade Wheel (Lower 1 10 089120406098 Spring Washer (M5 3 11 089120406097 Screw (M5 x 16 mm 3

WARNING: Improper repair of your BAND SAW or when ordering repair parts.

MODEL NUMBER BS904G

The model number will be performed by a Ryobi Authorized Service Center. RYOBI 9 in damage to the motor housing.

Ryobi A25RT02G Reviews

Do you have an experience with the Ryobi A25RT02G that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Ryobi yet.

Earn 750 points for your review!