Ridgid R4030 Support Question

Find answers below for this question about Ridgid R4030.Need a Ridgid R4030 manual? We have 1 online manual for this item!

Question posted by akopadt on April 24th, 2013

How Do I Adjust Square On My Ridgid R4030

The person who posted this question about this Ridgid product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Related Ridgid R4030 Manual Pages

Similar Questions

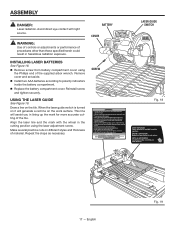

How Do You Replace The Laser Battery?

The laser on my Ridgid R4030 has gone out. How should I go about replacing it?

The laser on my Ridgid R4030 has gone out. How should I go about replacing it?

(Posted by Phat56007 3 years ago)

Height Adjustment Bolt Wearing Into Beating Block

I've had my r4331 planer for under a month and it seems to be more or less rubbing instead of cuttin...

I've had my r4331 planer for under a month and it seems to be more or less rubbing instead of cuttin...

(Posted by Bbenson2367 3 years ago)

How To Adjuest Air Press On Ridgid R350che

I can't fine in the operators manual for my r350che that part that tells me how to adj. the pres. On...

I can't fine in the operators manual for my r350che that part that tells me how to adj. the pres. On...

(Posted by Rivergod177 9 years ago)