Ridgid R350CHE Support and Manuals

Get Help and Manuals for this Ridgid item

View All Support Options Below

Free Ridgid R350CHE manuals!

Problems with Ridgid R350CHE?

Ask a Question

Free Ridgid R350CHE manuals!

Problems with Ridgid R350CHE?

Ask a Question

Most Recent Ridgid R350CHE Questions

Auto Actuation Not Functional

When I Depress the contact tipand pull the trigger it functions but when I try to switch over to aut...

When I Depress the contact tipand pull the trigger it functions but when I try to switch over to aut...

(Posted by jeffyoungrmt 5 years ago)

How To Adjuest Air Press On Ridgid R350che

I can't fine in the operators manual for my r350che that part that tells me how to adj. the pres. On...

I can't fine in the operators manual for my r350che that part that tells me how to adj. the pres. On...

(Posted by Rivergod177 9 years ago)

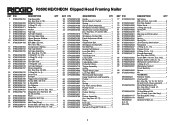

Popular Ridgid R350CHE Manual Pages

Ridgid R350CHE Reviews

We have not received any reviews for Ridgid yet.