Ridgid R350RHE Support and Manuals

Get Help and Manuals for this Ridgid item

View All Support Options Below

Free Ridgid R350RHE manuals!

Problems with Ridgid R350RHE?

Ask a Question

Free Ridgid R350RHE manuals!

Problems with Ridgid R350RHE?

Ask a Question

Most Recent Ridgid R350RHE Questions

Discontinued Part

Upper plastic bumper disintegrated, Part HM079005004079 is discontinued and no other replacement par...

Upper plastic bumper disintegrated, Part HM079005004079 is discontinued and no other replacement par...

(Posted by irvgoeschel 1 year ago)

I Have Air Coming Out Of The Top Of My R350rhe.doesnt Work

my R350RHE has air flow coming out of the top all the time (exhaust area).nail gun doesnt work.How d...

my R350RHE has air flow coming out of the top all the time (exhaust area).nail gun doesnt work.How d...

(Posted by heimlichelectric 2 years ago)

How Do You Remove The Spring Pins In Order To Remove The Trigger Valve Assembly

Rigid Framing Nailer RH350RHE:I have a rebuild kit that includes a new trigger valve assembly (part ...

Rigid Framing Nailer RH350RHE:I have a rebuild kit that includes a new trigger valve assembly (part ...

(Posted by ardvark02 9 years ago)

Is There A Trick To Reattaching The Exhaust Chamber?

I took off the exhaust chamber and now I can't seem to get it back on. I can get it most of the way ...

I took off the exhaust chamber and now I can't seem to get it back on. I can get it most of the way ...

(Posted by Kleind 9 years ago)

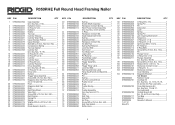

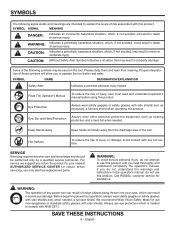

Popular Ridgid R350RHE Manual Pages

Ridgid R350RHE Reviews

We have not received any reviews for Ridgid yet.