Hitachi VB16Y Support Question

Find answers below for this question about Hitachi VB16Y - Rebar Cutter And Bender.Need a Hitachi VB16Y manual? We have 1 online manual for this item!

Question posted by palletfull36 on January 18th, 2014

Angle Bending Not Precise . Please Help Asap

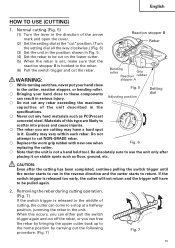

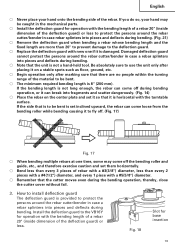

Angle bending not precise . PLEASE HELP ASAP I recently bought a new vb16y hitachi rebar bender and cutter. it doesn't bend at the angle it says it is going to bend. is there some type of reset somewhere

Current Answers

Related Hitachi VB16Y Manual Pages

Similar Questions

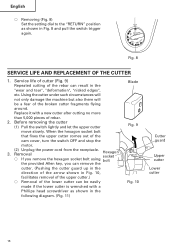

Rebar Bender Cutter Won't Cut

While using my hitachi rebar bender to cut #4 rebar the cutters got stuck in the closed position and...

While using my hitachi rebar bender to cut #4 rebar the cutters got stuck in the closed position and...

(Posted by noconnor 1 year ago)

Why Did My Cutter Stop Cutting And Bending. Is There A Reset Button ?

(Posted by jdlconcrete 2 years ago)

I Can Adjust The Mitre Angle All The Way On The Right But It Stops At 10 Degrees

I can adjust the mitre angle all the way on the right but it won't budge past 10 degrees when I try ...

I can adjust the mitre angle all the way on the right but it won't budge past 10 degrees when I try ...

(Posted by rivuletcottage 9 years ago)

Dial Is Set To 90 Degrees But Wont Bend Past 65-70 Degree Help!

So I tried to bend and i had the dial set to 90 degrees but after it was finished the bar was only b...

So I tried to bend and i had the dial set to 90 degrees but after it was finished the bar was only b...

(Posted by kaylamcconnell17 9 years ago)

I Require A Vise Assembly For A Hitachi C8fse Slide Compound Saw, Please Help

I have an Hitachi C8FSE Slide Compound Saw and wish to purchase a Vise Assembly, can anybody help?

I have an Hitachi C8FSE Slide Compound Saw and wish to purchase a Vise Assembly, can anybody help?

(Posted by davaki 10 years ago)