Hitachi VB16Y Support Question

Find answers below for this question about Hitachi VB16Y - Rebar Cutter And Bender.Need a Hitachi VB16Y manual? We have 1 online manual for this item!

Question posted by kaylamcconnell17 on September 25th, 2014

Dial Is Set To 90 Degrees But Wont Bend Past 65-70 Degree Help!

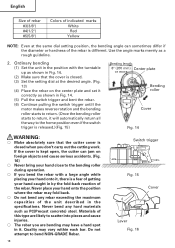

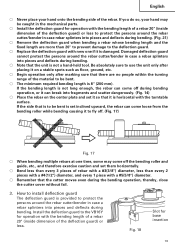

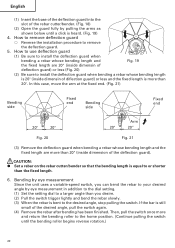

So I tried to bend and i had the dial set to 90 degrees but after it was finished the bar was only bent to 65- 70 degree bend. but like i said the dial was set to 90. How do i fix this? could it be possible the dial got thrown off some how? if so how could i fix it to bend all the way to 90?

Current Answers

Related Hitachi VB16Y Manual Pages

Similar Questions

Was Cutting And It Quit With Rebar Stuck In Jaw.

(Posted by mlemesany 2 years ago)

Nt65ga Will Not Fire

NT65GA Does not fire when trigger is pulled. Battery has full charge.

NT65GA Does not fire when trigger is pulled. Battery has full charge.

(Posted by dmcgeeoo6 6 years ago)

Try To Bend Bar And Don't Turn Wit No Bar A Will Turn

(Posted by pierrrerousseau1 9 years ago)

Angle Bending Not Precise . Please Help Asap

Angle bending not precise . PLEASE HELP ASAP I recently bought a new vb16y hitachi rebar bender and ...

Angle bending not precise . PLEASE HELP ASAP I recently bought a new vb16y hitachi rebar bender and ...

(Posted by palletfull36 10 years ago)

Adjusting The Bevel 90 Degree Stop On A C12rsh / Bevel Out Of Alignment.

where can I find directions to the above question title

where can I find directions to the above question title

(Posted by lanyalapunta 12 years ago)