Hitachi C12RSH Support Question

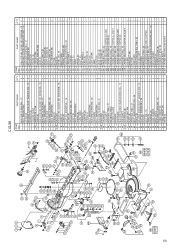

Find answers below for this question about Hitachi C12RSH - 305mm Slide Compound Mitre Saw.Need a Hitachi C12RSH manual? We have 2 online manuals for this item!

Question posted by lanyalapunta on August 17th, 2011

Adjusting The Bevel 90 Degree Stop On A C12rsh / Bevel Out Of Alignment.

where can I find directions to the above question title

Current Answers

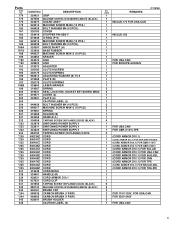

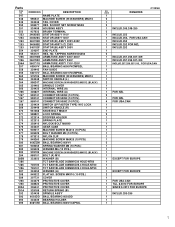

Related Hitachi C12RSH Manual Pages

Similar Questions

Dial Is Set To 90 Degrees But Wont Bend Past 65-70 Degree Help!

So I tried to bend and i had the dial set to 90 degrees but after it was finished the bar was only b...

So I tried to bend and i had the dial set to 90 degrees but after it was finished the bar was only b...

(Posted by kaylamcconnell17 9 years ago)

C12rsh Laser Marker

Hi the laser has stopped working on my saw and wandering if it is common fault or a one off and if s...

Hi the laser has stopped working on my saw and wandering if it is common fault or a one off and if s...

(Posted by Woodyrally 9 years ago)

How To Adjust Cut Depth Hitachi 10 Compound Miter Saw Manual

(Posted by dbrag 9 years ago)

Bevel Lock Slips

When I move the blade to the right for beveling the locking mechanism can't keep it in place after a...

When I move the blade to the right for beveling the locking mechanism can't keep it in place after a...

(Posted by rwang1 12 years ago)

Where Can I Get A Free Manual On The Hitachi C12rsh 12' Slide Compound Miter Saw

(Posted by kathy86883 14 years ago)