Hitachi C10FCE2 Support Question

Find answers below for this question about Hitachi C10FCE2 - 10 Inch Compound Miter Saw.Need a Hitachi C10FCE2 manual? We have 2 online manuals for this item!

Question posted by dbrag on May 2nd, 2014

How To Adjust Cut Depth Hitachi 10 Compound Miter Saw Manual

The person who posted this question about this Hitachi product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

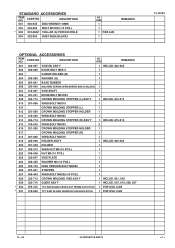

Related Hitachi C10FCE2 Manual Pages

Similar Questions

326-700 This Part Has Been Discontinued. I Need A Replacement For This Part.

I need a replacement for this part, it has been discontinued . My Hitachi Miter saw C10FCE2 the swit...

I need a replacement for this part, it has been discontinued . My Hitachi Miter saw C10FCE2 the swit...

(Posted by TXpallets 9 years ago)

How To Square The Head On An Hitachi Miter Saw

(Posted by afajab 10 years ago)

How To Square A Hitachi Miter Saw

(Posted by prisibr 10 years ago)

I Have A Nv 50ap3. Can I Adjust The Depth Of The Nail So I Can Use Only Nails?

I don't want to use caps but the nails are not driven all the way down. Is there a way to adjust for...

I don't want to use caps but the nails are not driven all the way down. Is there a way to adjust for...

(Posted by jph99980 11 years ago)

Where Can I Get A Free Manual On The Hitachi C12rsh 12' Slide Compound Miter Saw

(Posted by kathy86883 14 years ago)