Hitachi VB16Y Support Question

Find answers below for this question about Hitachi VB16Y - Rebar Cutter And Bender.Need a Hitachi VB16Y manual? We have 1 online manual for this item!

Question posted by jdlconcrete on July 12th, 2021

Why Did My Cutter Stop Cutting And Bending. Is There A Reset Button ?

Current Answers

Answer #1: Posted by Odin on July 12th, 2021 5:58 PM

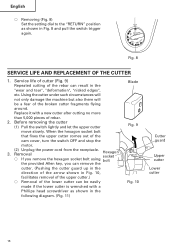

All power tools will eventually require servicing or replacement of parts because of wear from normal use.

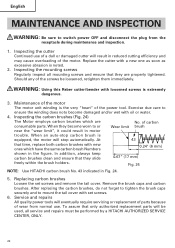

The motor employs carbon brushes, which are consumable parts. When they become worn to or near the wear limit,you could have motor trouble.

When an auto-stop carbon brush is equipped, the motor will stop automatically. At that time, replace both carbon brushes with new ones have the same carbon brush numbers [see graphic, https://tinyurl.com/yzejtltq]. In addition, always keep carbon brushes clean and ensure that they slide freely within the brush holders.

If the issue persists or if you require further advice, you may want to consult the company: use the contact information at https://www.contacthelp.com/hitachi.

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

Answer #2: Posted by SonuKumar on July 12th, 2021 10:24 PM

https://www.youtube.com/watch?v=xlFQvlvdnkc

https://www.youtube.com/watch?v=xlFQvlvdnkc&t=70s

https://www.youtube.com/watch?v=xlFQvlvdnkc&t=83s

https://www.youtube.com/watch?v=xlFQvlvdnkc&t=98s

All power tools will eventually require servicing or replacement of parts because of wear from normal use.

The motor employs carbon brushes, which are consumable parts. When they become worn to or near the wear limit,you could have motor trouble.

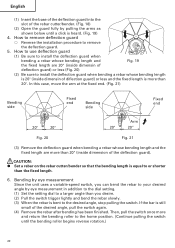

https://www.hikoki-powertools.com/manual_view_export/pdf/C99105011_VB16Y_404.pdf

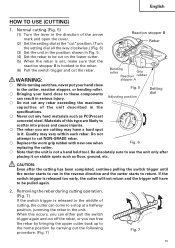

refer to page 3-7

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Hitachi VB16Y Manual Pages

Similar Questions

While using my hitachi rebar bender to cut #4 rebar the cutters got stuck in the closed position and...

nail gun gives screeching noise when firing nails sounds like fan motor but not sure when activated ...

My router will not turn on. It spins free by hand. Could the brushes be bad. Is there a reset button...