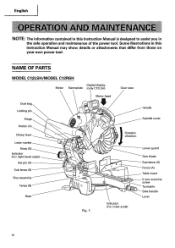

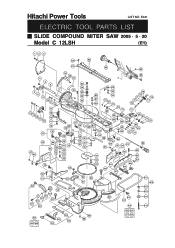

Hitachi C12LSH Support Question

Find answers below for this question about Hitachi C12LSH - 12" Dual Bevel Sliding Compound Miter Saw.Need a Hitachi C12LSH manual? We have 2 online manuals for this item!

Question posted by rivuletcottage on April 15th, 2015

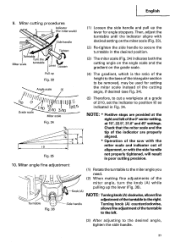

I Can Adjust The Mitre Angle All The Way On The Right But It Stops At 10 Degrees

I can adjust the mitre angle all the way on the right but it won't budge past 10 degrees when I try to adjust it to the left. This is a brand new saw and i am just setting it up.

Current Answers

Answer #1: Posted by hzplj9 on April 21st, 2015 1:40 PM

My suggestion is to verify that you have followed the correct procedure for assembly. Check that there is not anything underneath that is stopping it move to the left. If that proves a fault then returning it to your dealer will be the option. I have placed a link to your device.

http://www.ultimatehandyman.org/manuals/powertools/hitachi/6.pdf

Related Hitachi C12LSH Manual Pages

Similar Questions

C10fs Compound Miter Saw Bearing Replacement

how do I remove the bearing from the armature

how do I remove the bearing from the armature

(Posted by Bobster8820 3 years ago)

Hitachi C12lsh Wiring Power Swith

I neglected to take a picture of the wiring of the switch. It has 3 connections.... One for the powe...

I neglected to take a picture of the wiring of the switch. It has 3 connections.... One for the powe...

(Posted by wsigurdson 9 years ago)

How To Adjust Cut Depth Hitachi 10 Compound Miter Saw Manual

(Posted by dbrag 9 years ago)

How Do I Set Laser On Hitachi C12lsh?

(Posted by Anonymous-23407 13 years ago)

Where Can I Get A Free Manual On The Hitachi C12rsh 12' Slide Compound Miter Saw

(Posted by kathy86883 14 years ago)