Hitachi c10fs Support Question

Find answers below for this question about Hitachi c10fs - 940543 3/8 Box Wrench.Need a Hitachi c10fs manual? We have 3 online manuals for this item!

Question posted by Bobster8820 on July 13th, 2020

C10fs Compound Miter Saw Bearing Replacement

how do I remove the bearing from the armature

Current Answers

Answer #1: Posted by Odin on July 13th, 2020 3:07 PM

There are three videos on this issue at https://ishort.ink/Hhfy. Good luck!

Hope this is useful. Please don't forget to click the Accept This Answer button if you do accept it. My aim is to provide reliable helpful answers, not just a lot of them. See https://www.helpowl.com/profile/Odin.

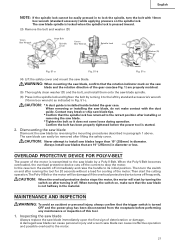

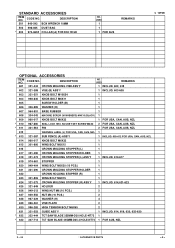

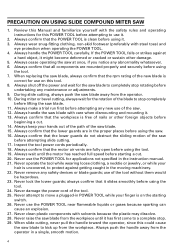

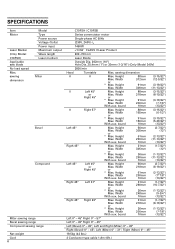

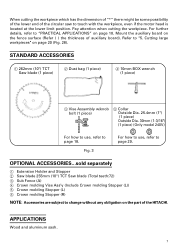

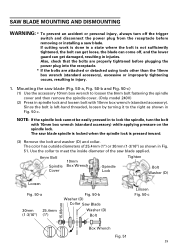

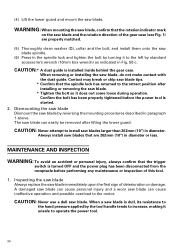

Related Hitachi c10fs Manual Pages

Similar Questions

Wiring Diagram For Hitachi Miter Saw

I bought a switch for Hitachi c10 fc2 & need a wiring diagram to hook it upThank You Dave

I bought a switch for Hitachi c10 fc2 & need a wiring diagram to hook it upThank You Dave

(Posted by delliott49 7 years ago)

How Do You Replace In A Hitachi C10fs Compound Saw

(Posted by nadar 9 years ago)

How To Adjust Cut Depth Hitachi 10 Compound Miter Saw Manual

(Posted by dbrag 10 years ago)

How To Square A Hitachi Miter Saw

(Posted by prisibr 10 years ago)

Where Can I Get A Free Manual On The Hitachi C12rsh 12' Slide Compound Miter Saw

(Posted by kathy86883 14 years ago)