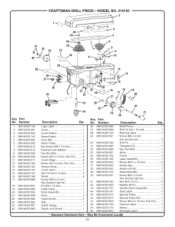

Craftsman 21914 Support Question

Find answers below for this question about Craftsman 21914 - 12 in. Drill Press.Need a Craftsman 21914 manual? We have 1 online manual for this item!

Question posted by v12Ashr on May 19th, 2014

How To Remove The Chuck From A Craftsman 9 Drill Press

The person who posted this question about this Craftsman product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

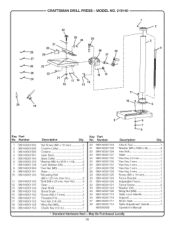

Related Craftsman 21914 Manual Pages

Similar Questions

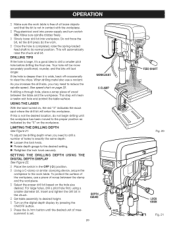

Removal Of Chuck

I am trying to remove the old chuck to replace it. I removed the screw inside the chuck. I put an al...

I am trying to remove the old chuck to replace it. I removed the screw inside the chuck. I put an al...

(Posted by joynjershore 1 year ago)

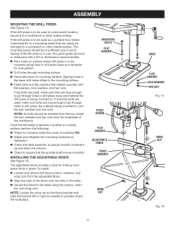

Assembly Video

is there an online video on how to assemble the 12" drill press?

is there an online video on how to assemble the 12" drill press?

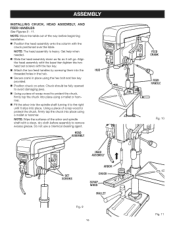

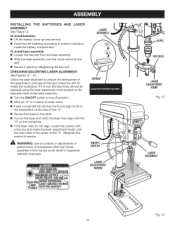

(Posted by davisgirl51 10 years ago)

Drill Model315222690 Chuck Replacement?

I want to replace the chuck on my drill.

I want to replace the chuck on my drill.

(Posted by greatwhitewally 12 years ago)

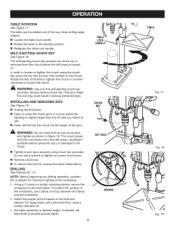

Craftsman 21914 Quill Distance?

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

(Posted by remondi 12 years ago)