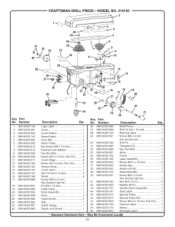

Craftsman 21914 Support Question

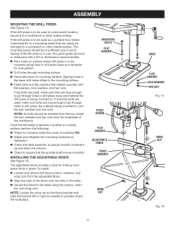

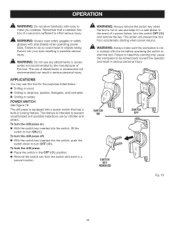

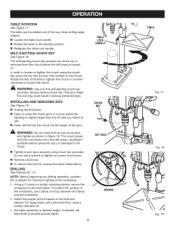

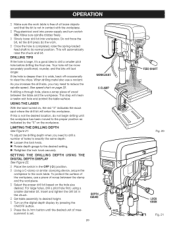

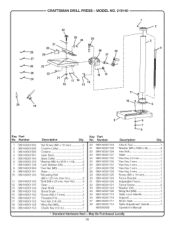

Find answers below for this question about Craftsman 21914 - 12 in. Drill Press.Need a Craftsman 21914 manual? We have 1 online manual for this item!

Question posted by davisgirl51 on October 25th, 2013

Assembly Video

is there an online video on how to assemble the 12" drill press?

Current Answers

Related Craftsman 21914 Manual Pages

Similar Questions

How To Remove The Chuck From A Craftsman 9 Drill Press

(Posted by v12Ashr 9 years ago)

How Do I Assemble The Gears And Housing For A Craftsman 19.2v Cordless Drill.

(Posted by trbaker64 11 years ago)

Gear Assembly For A Ctaftsman 19.2v Cordless Drill

i need to find adiagram or instructions on how to reasemble the gears inside a craftsman cordless dr...

i need to find adiagram or instructions on how to reasemble the gears inside a craftsman cordless dr...

(Posted by trbaker64 12 years ago)

Lower Blade Guard Assembly

The ''arm'' broke. Is there any way I can buy just the ''arm'' and not the whole assembly?

The ''arm'' broke. Is there any way I can buy just the ''arm'' and not the whole assembly?

(Posted by cheesyspisi 12 years ago)

Craftsman 21914 Quill Distance?

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

(Posted by remondi 12 years ago)