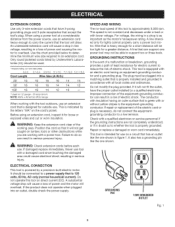

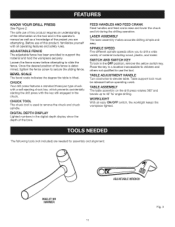

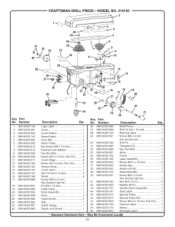

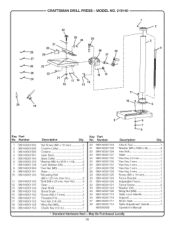

Craftsman 21914 Support Question

Find answers below for this question about Craftsman 21914 - 12 in. Drill Press.Need a Craftsman 21914 manual? We have 1 online manual for this item!

Question posted by helpowl14425 on October 22nd, 2012

Front Pulley

How do I remove the quill pulley to replace it?

Current Answers

Related Craftsman 21914 Manual Pages

Similar Questions

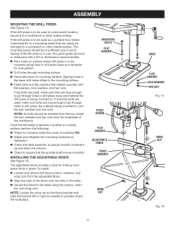

The Stud That The Height Adjustment Lever Goes On Is Striped. Replaceable Or Wh

Is the stud that holds height adjustment replaceable? Or what is the thread size to retread it. Has ...

Is the stud that holds height adjustment replaceable? Or what is the thread size to retread it. Has ...

(Posted by jabutler470 5 months ago)

How To Remove The Chuck From A Craftsman 9 Drill Press

(Posted by v12Ashr 9 years ago)

Remove Driven Pulley On Band Saw Model 351.214190

How Do You Remove Driver Pulley On Band Saw Model351.214190

How Do You Remove Driver Pulley On Band Saw Model351.214190

(Posted by AVERBECK 9 years ago)

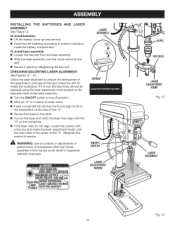

Assembly Video

is there an online video on how to assemble the 12" drill press?

is there an online video on how to assemble the 12" drill press?

(Posted by davisgirl51 10 years ago)

Craftsman 21914 Quill Distance?

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

What is the quill distance for the Craftsman 21914 - 12 inch drill press? I need to fit a mortise at...

(Posted by remondi 12 years ago)