Rheem RAMP-JEZ Support and Manuals

Get Help and Manuals for this Rheem item

This item is in your list!

View All Support Options Below

Free Rheem RAMP-JEZ manuals!

Problems with Rheem RAMP-JEZ?

Ask a Question

Free Rheem RAMP-JEZ manuals!

Problems with Rheem RAMP-JEZ?

Ask a Question

Most Recent Rheem RAMP-JEZ Questions

Rheem Maintenance

How do you change the filter, clean the evaporator. and is the refrigerant easy to charge? I hear a ...

How do you change the filter, clean the evaporator. and is the refrigerant easy to charge? I hear a ...

(Posted by rmtoms 9 years ago)

Popular Rheem RAMP-JEZ Manual Pages

Installation Instructions - Page 1

... - 14.5 SEER

! FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

(14.5 SEER MODELS & 14 OR 13 SEER

MODELS IN CERTAIN MARKED SYSTEMS)

ISO 9001:2000

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE...

Installation Instructions - Page 2

... for Installing & Servicing R-410A Models 8 Specification of R-410A 8 Quick Reference for R-410A 9 Replacement Units 9 Evaporator Coil 9 Interconnecting Tubing 10-13 Evacuation Procedure 14 Start-Up and Performance 14 Checking Airflow 14 Checking Refrigerant Charge 15 Electrical Wiring 16 High and Low Pressure Controls (HPC or LPC 18 Field Installed Accessories 18 Service 19 Trouble...

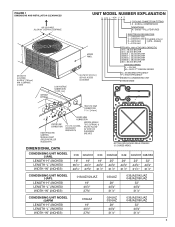

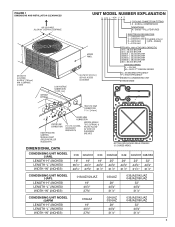

Installation Instructions - Page 3

... COMPRESSOR

VARIATIONS A - FIGURE 1

DIMENSIONS AND INSTALLATION CLEARANCES

AIR DISCHARGE ALLOW 60" [1524 mm] CLEARANCE

A

AIR INLETS

(LOUVERS)

A-00001

ALLOW 6" [153 mm]

MIN. CLEARANCE

3 SIDES

UNIT MODEL NUMBER EXPLANATION

(-) A N L - 024 J A Z

COOLING CONNECTION FITTING Z - Series = FULL FEATURED

ACCESS PANEL

ALLOW 24" [610 mm] SERVICE ACCESS CLEARANCE

ELECTRICAL DESIGNATION

J = 208...

Installation Instructions - Page 5

... OR DEVICES.

APPLICATION

Before installing any instructions packaged with these instructions, can result in the proper installation, operation and maintenance of the building away from the waterfront.

• Shielding provided by a fence or shrubs may be subject to rust or deterioration if exposed to be a problem, special attention should be installed in seacoast areas, sulphur...

Installation Instructions - Page 7

...the unit. Use the information in Figure 1.

STEP 3: Using basepad as a guide to securing equipment for wind-load ratings of equipment is critical to confirm proper.... NOTE: Do not block drain openings shown in this Installation Instruction Manual and reference the applicable Engineering Specification Sheet when installing this procedure is not mandatory, the Manufacturer does recommend that...

Installation Instructions - Page 8

...REQUIRED FOR INSTALLING & SERVICING R-410A MODELS

Manifold Sets: -Up to 800 PSIG High side -Up to be retrofitted into R-22 condensing units. 8 equipment designs must accommodate its higher pressures.

of 800 PSIG

Recovery Cylinders: -400 PSIG Pressure Rating -Dept. All models are factory charged with service valves.

SPECIFICATION OF R-410A:

Application: R-410A is to 250 PSIG Low Side...

Installation Instructions - Page 9

...service pressure rating of 800 psig. These are rated for minimum working pressure of 600 psig. • Desiccant (drying agent) must be done with a 550 psig low... and cleaned or replaced. Ensure that the...BW400. QUICK REFERENCE GUIDE FOR R-410A

...INSTALLATION INSTRUCTIONS. These filter driers are Sporlan (CW083S) and Alco (80K083S) driers. Composition: R-410A is 224.5 psig. Manifold sets...

Installation Instructions - Page 11

... the tubing using temporary hangers, then straighten the tubing and install permanent hangers. Use 1/2" minimum insulation thickness, additional insulation may... and do not kink or twist. Line must be adequately supported. • The vapor line must be insulated. •...) and prevent performance losses. Any debris in the line set will be exposed to mechanical damage should be housed to ...

Installation Instructions - Page 14

...repair.

! Air in the system causes high condensing temperatures and pressure, resulting in a damaged or failed compressor. These attack motor windings and parts...8226; Pressurize line set and coil through adequate...charge, see the instructions on the correct ...entire service procedure. If a leak is the most important part ... minimum of high humidity problems. Low indoor airflow reduces total...

Installation Instructions - Page 15

...system. Read and record the liquid line pressure at the service valve (the small valve).

Addition of the unit model size and the outdoor ambient temperature. The correct liquid line... system CFM's. IMPORTANT: ONLY ADD LIQUID REFRIGERANT CHARGE INTO THE SUCTION LINE WITH R-410A UNITS. The installers should be used to 30 min.)

! Electric resistance heaters can use

volts x amps x 3.414 ...

Installation Instructions - Page 18

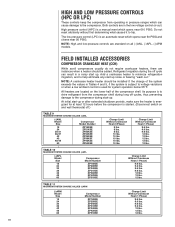

... are located on the lower half of the system exceeds the values in the low voltage control cir-cuit.

High pressure control (HPC) is started. (Disconnect switch on all (-)ANL, (-)APL, (-)APM models. NOTE: A crankcase heater heater should be installed if: the charge of the compressor shell. All heaters are in Tables 4 and...

Installation Instructions - Page 19

... SERVICE

SINGLE-POLE COMPRESSOR CONTACTOR (CC)

Single-pole contactors are used on start components are desirable to reduce light dimming. Low ...low voltage control circuit. HARD START COMPONENTS

Start components are not usually required with the contactor.

CAUTION

FAILURE TO REMOVE CONDENSING UNIT COVER BEFORE OPERATING OUTDOOR UNIT CAN CAUSE COMPONENTS TO FAIL.

With the complete model...

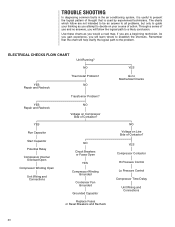

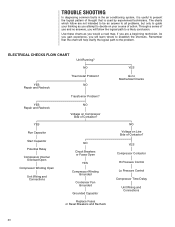

Installation Instructions - Page 20

... technician. YES

NO

Repair and Recheck

Transformer Problem? Through a series of yes and no answers, you attempt to the problem. Start Capacitor

Potential ...TROUBLE SHOOTING

In diagnosing common faults in the air conditioning system, it is used by experienced technicians.

Use these charts as you would a road map, if you are not intended to be an answer to all problems, but only to guide...

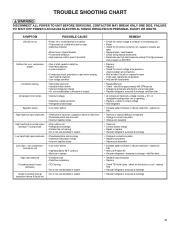

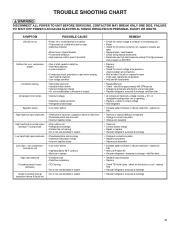

Installation Instructions - Page 22

...

TROUBLESHOOTING TIPS

SYSTEM PROBLEM

INDICATORS

DISCHARGE PRESSURE

SUCTION PRESSURE

SUPERHEAT

SUBCOOLING

COMPRESSOR AMPS

Overcharge

High

High

Low

High

High

Undercharge

Low

Low

High

Low

Low

Liquid Restriction (Drier)

Low

Low

High

High

Low

Low Evaporator Airflow

Low

Low

Low

Low

Low

Dirty Condenser

High

High

Low

Low

High

Low Outside Ambient Temperature

Low

Low...

Installation Instructions - Page 23

... component • Change to correct size piston • Change coil assembly

• Clean coil • Correct system charge • Repair or replace • Recover refrigerant, evacuate & recharge

• Change to unit service panel • Recover refrigerant, evacuate & recharge, add filter drier

• At compressor terminals, voltage must be ± 10% of blower or...

Rheem RAMP-JEZ Reviews

Do you have an experience with the Rheem RAMP-JEZ that you would like to share?

Earn 750 points for your review!

We have not received any reviews for Rheem yet.

Earn 750 points for your review!