Ryobi TSS101L Support Question

Find answers below for this question about Ryobi TSS101L.Need a Ryobi TSS101L manual? We have 4 online manuals for this item!

Question posted by shaunnyg2001 on July 15th, 2011

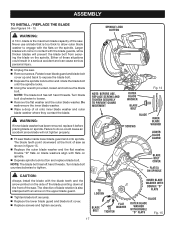

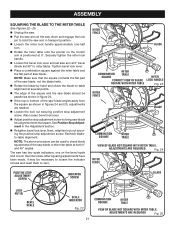

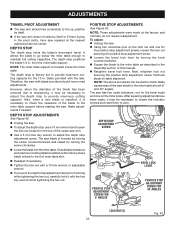

Blade Not Going On Correctly

I recently bought the Ryobi mitre saw TSS101L used with no blade, turned it on seamed to work fine, went to put on a 10"blade went on OK but it doesn't line up with the throat plate. i've done it now several times same result I made sure everything was square,but still the same thing. it seams as though the inner blade washer is out about a quarter inch too far I really don't want to remove the motor, is there any thing I'm doing wrong?

Current Answers

Related Ryobi TSS101L Manual Pages

Similar Questions

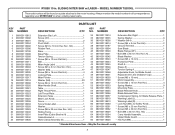

Is There A Replacement For Ryobi Tss101l D Handle & Switch?

Part #s for above: 089100121610 089100121112 Have apparently discontinued. Does anyone have a fix?

Part #s for above: 089100121610 089100121112 Have apparently discontinued. Does anyone have a fix?

(Posted by Math72285 3 years ago)

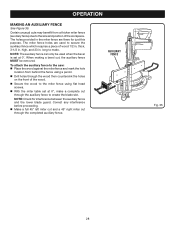

Fence

Will the fence for the TSS101L fit on a TSS100L Ryobi mitre saw?

Will the fence for the TSS101L fit on a TSS100L Ryobi mitre saw?

(Posted by pcarneyconstruction 7 years ago)

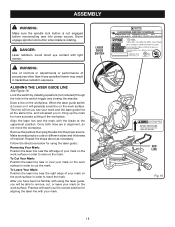

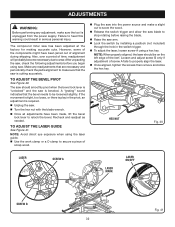

Ryobi Tss101l Laser Not Working?

I have a brand new Ryobi TSS101L and I see no evidence of a laser working. I looked through the manu...

I have a brand new Ryobi TSS101L and I see no evidence of a laser working. I looked through the manu...

(Posted by linexyc 11 years ago)

Inner Wheel Washer Vs Outer Wheel Washer And How Do Each Go Onto Arbor?

How do I tell the differencce between the inner wheel washer and the outer wheel washer andhow (what...

How do I tell the differencce between the inner wheel washer and the outer wheel washer andhow (what...

(Posted by stevenfrsmith 12 years ago)

Ryobi Rts30 Dado Throat Plate And Dado Blade

I am looking for the correct dado throat plate and dado saw blades for my Ryobi RTS30 10" table saw....

I am looking for the correct dado throat plate and dado saw blades for my Ryobi RTS30 10" table saw....

(Posted by daleemcmillan 12 years ago)