Ryobi DP102L Support Question

Find answers below for this question about Ryobi DP102L.Need a Ryobi DP102L manual? We have 4 online manuals for this item!

Question posted by tdinaz on July 14th, 2011

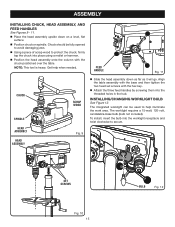

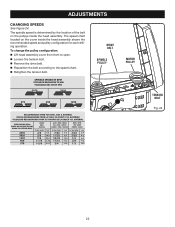

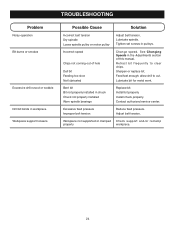

Tension Bolt Rotates But Pulleys Don't Tighten Not Loosen The Belt?

The tension bolt on my Ryobi 102L will rotate but the belts will not tighten nor loosen. Why?

Current Answers

Related Ryobi DP102L Manual Pages

Similar Questions

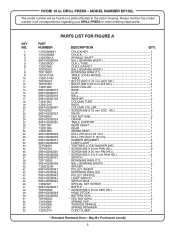

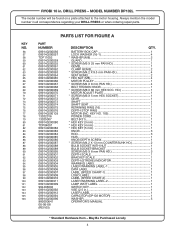

Pulley Shaft Hold Down Nut Approximately 5/8 Fine Threads

the schematic shows a 1 inch X 20 nut 1 inch is way too la

the schematic shows a 1 inch X 20 nut 1 inch is way too la

(Posted by Garliced 2 years ago)

Pulley Insert

The pulley insert for my DP102L drillpress has snapped into. The break is at the diameter change of ...

The pulley insert for my DP102L drillpress has snapped into. The break is at the diameter change of ...

(Posted by dannylandrum 5 years ago)

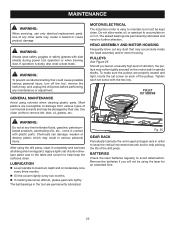

Drive Belt Comes Off Motor Pulley

This happens even after adjusting the motor for different tension levels. It will run maybe 20/30 se...

This happens even after adjusting the motor for different tension levels. It will run maybe 20/30 se...

(Posted by jboyd17770 7 years ago)

Belt Not Driving Chuck.

In fact, I can hold the chuck still while the motor and belt are working. I looked in the manual and...

In fact, I can hold the chuck still while the motor and belt are working. I looked in the manual and...

(Posted by revdocpop1 8 years ago)

Blade Rotational Direction.

I am not able to cut hardwood from my Ryobi RLS1351. I don't have any problem cutting laminate floor...

I am not able to cut hardwood from my Ryobi RLS1351. I don't have any problem cutting laminate floor...

(Posted by bymatias 12 years ago)