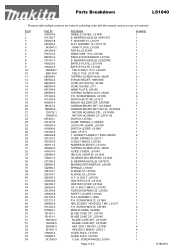

Makita LS1040 Support Question

Find answers below for this question about Makita LS1040.Need a Makita LS1040 manual? We have 2 online manuals for this item!

Question posted by charlesdavidferguson28 on March 24th, 2013

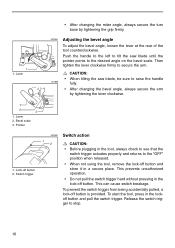

Dropped My Ls1040 Of The Bench Whilst In The Open Position

the machine will not now come down to snip the timber there is a bar under the saw guard which is connected to the safety release button it seems to have been pushed forward because it catches the nut that holds the saw blade

Current Answers

Related Makita LS1040 Manual Pages

Similar Questions

Release Saw Arm

how do you release ether saw to place timber on the plate for cut

how do you release ether saw to place timber on the plate for cut

(Posted by jcunningham56752 1 year ago)

Broken Bits

I purchased my Makita HR2811F around 6 month ago and it broke 6 chisel bits in the choke area. What ...

I purchased my Makita HR2811F around 6 month ago and it broke 6 chisel bits in the choke area. What ...

(Posted by teinpr 2 years ago)

Makita Hr5001c Motor Problem

The motor runs at correct rev's but drops a slight bit of rev's every revolution but then picks up.C...

The motor runs at correct rev's but drops a slight bit of rev's every revolution but then picks up.C...

(Posted by tim50103 7 years ago)

Tool Not Working

I bought a new makita LXPH01 Hammer Drill. I put a fully charged lit-ion battery 3.0a but when I pr...

I bought a new makita LXPH01 Hammer Drill. I put a fully charged lit-ion battery 3.0a but when I pr...

(Posted by shiki98 11 years ago)