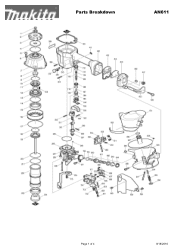

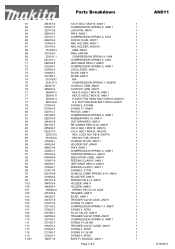

Makita AN611 Support Question

Find answers below for this question about Makita AN611.Need a Makita AN611 manual? We have 2 online manuals for this item!

Question posted by noblebuildingllc on October 6th, 2020

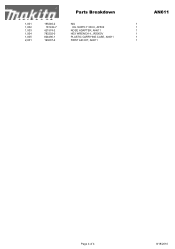

Contact Arm

Current Answers

Answer #1: Posted by hzplj9 on October 6th, 2020 1:12 PM

There are part numbers attached to the document

https://www.manualslib.com/m/makita+an611.html

There is also a user guide but I assume you already have one.

Hope that helps.

Related Makita AN611 Manual Pages

Similar Questions

cant find a service manual for this vacuum

how do you release ether saw to place timber on the plate for cut

I need to know how much and what kind of oil goes in a makita saw 5477nb

I bought a new makita LXPH01 Hammer Drill. I put a fully charged lit-ion battery 3.0a but when I pr...